In the world of live television, there’s no pause button. A significant transformer fire at KARE 11’s Golden Valley, Minn. facility forced a full evacuation of the building. While there were no injuries, employees remained unable to access the facility, and the extent of damage to critical broadcast systems was initially unclear. Egan Company responded swiftly with a complete electrical infrastructure replacement to restore reliable operations and help KARE 11 return to normal broadcasting as quickly as possible.

The original electrical system installed in the 1970s – by a contractor not affiliated with Egan Company – featured an outdoor, weatherproof-rated bus duct running above ground into the indoor utility room. Building engineers, facilities managers, and Egan experts believe that prolonged exposure to Minnesota’s severe weather over the past five decades contributed to the system’s failure.

Jesse Gesme, Egan Company Project Manager, said, “It was great to see everyone come together with all hands on deck, multiple project managers, estimators, and outside vendors, working with urgency to restore operations. The teamwork and quick coordination with the KARE 11 team made a big difference in getting the job done.”

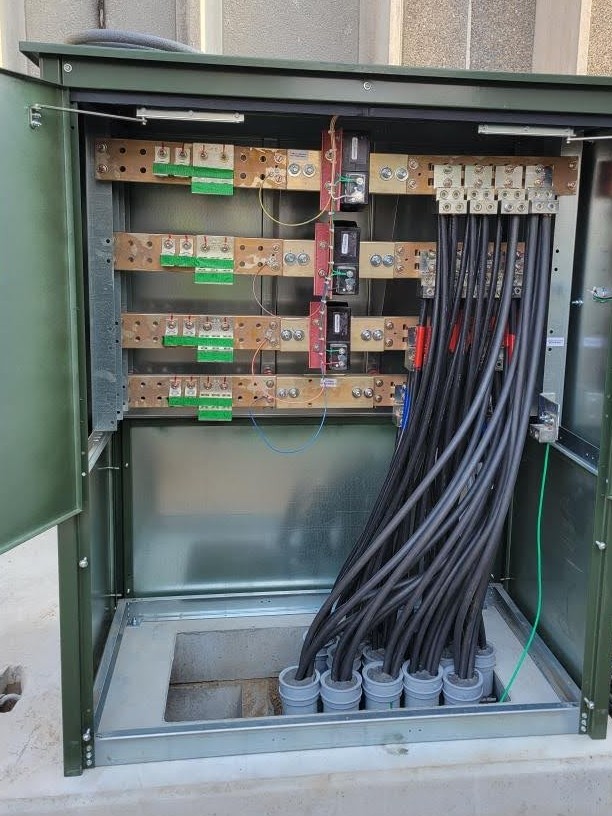

Egan crews mobilized immediately when they got the call to restore power and begin installing new electrical systems to meet modern codes and standards. By noon the following day, the temporary outdoor generator’s final connections were made to re-energize the station and work began on the installation of new electrical services and infrastructure both inside and outside the building. The final switchover from generator power to the upgraded permanent system took place nine days after the fire.

“We rely on Egan’s expertise and the quality of their work – both of which have met or exceeded our expectations,” said Marty McAlpine, KARE 11 Broadcast Engineer. “We valued their collaboration, approachability, and continual communication as the project progressed. The crew was with us every step of the way. It was clear they had our best interests front and center. Every day, multiple times throughout the day, they kept us in the loop and synced up at every stage of the project. They listened and understood our business needs and operations and answered every question we had. There were no shortcuts or loose ends. They were always on time, worked as long as it took, and ultimately completed the work on schedule.”

Crews worked closely with KARE 11 staff to ensure operations continued without risk to employees or visitors and station leadership has expressed confidence in Egan’s handling of the emergency and the commitment to quickly restoring reliable electrical service. Most importantly, consistent with Egan’s “Stay Safe” core value, safety remained at the core throughout this partnership and process. And crews kept safety a priority from start to finish.

MINNEAPOLIS, MN (July 1, 2020) – Egan Company, a Brooklyn Park specialty contractor and systems integrator, announced the promotion of Mike Tengwall to Senior Vice President and Electrical Group Leader. In this senior leadership role, Tengwall is responsible for overseeing business operations and strategy for Egan’s business unit that provides complete electrical services and process controls which includes engineering, a U.L. 508A panel shop and IntelliBatch, Egan’s concrete batching product.

MINNEAPOLIS, MN (July 1, 2020) – Egan Company, a Brooklyn Park specialty contractor and systems integrator, announced the promotion of Mike Tengwall to Senior Vice President and Electrical Group Leader. In this senior leadership role, Tengwall is responsible for overseeing business operations and strategy for Egan’s business unit that provides complete electrical services and process controls which includes engineering, a U.L. 508A panel shop and IntelliBatch, Egan’s concrete batching product.

For a second year, Finance & Commerce readers voted Egan Company as a top choice within the Best Electrical Contractor and Best Plumbing Company categories in the 2018 Reader Rankings.

For a second year, Finance & Commerce readers voted Egan Company as a top choice within the Best Electrical Contractor and Best Plumbing Company categories in the 2018 Reader Rankings.