As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site.

As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site.

The Fire Department, utility company, and an Egan technician were all dispatched out to the high school to assess the situation. Before anyone could enter the building, the Fire Department needed to clear it of smoke and verify it was safe to enter. They then had to await the  arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem.

arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem.

“As we were standing outside the school, we could hear the electrical busbar underground shorting and failing in the underground tunnel,” said Darrell Blazevic, Egan Company Account Manager. The school’s main electrical supply failed in a tunnel underneath the school, so smoke needed to be evacuated from there as well before we could begin investigating.”

Once the Fire Department and utility company had completed their work, Jason Lindula, Egan Company Safety Coordinator, reviewed the site for any potential hazards. Because all the electrical work needed to be done in an underground tunnel, any employee on site was required to be trained on Confined Space and Air Monitoring Systems before entering the tunnel.

Major Disruptions

Although classes were not in session, this power outage caused major disruptions, not just to the high school, but to the entire Mound-Westonka School District.

The main power had a catastrophic failure, and power was completely cut off throughout the school. And since the District’s fiber-optic network and communication server is held at the high school, they also had lost access to all methods of communication.

In addition to the entire District losing access to the server, there were also numerous activities still happening at the high school. Temporary power needed to be set up in order for them to resume as soon as possible. Within one week, Egan electricians had set up temporary power with a 480 volt generator the size of a semi-trailer. Temporary fiber cabling was also put down to provide an immediate solution to the loss of the District’s server.

Egan Company acted quickly and made us feel like they had a good handle on the problem.

-Phil Smith, Director of Facilities at Mound-Westonka Schools.

Digging in to Find a Permanent Solution

Knowing that the permanent power needed to be replaced as soon as possible, Egan’s team worked methodically and safely to get the District back on the grid. The main problem was the service entrance feeder had failed and heated up the electric busbar, causing the failure in the electrical feeder and fiber optic.

Earth excavation outside the school opened up a wall below grade to gain access to the tunnel and repair the damage from the failure. The utility company’s transformer, service entrance power  supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server.

supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server.

In less than two weeks, the entire school was back on permanent power and operating as normal.

“There were multiple things going on at once, and if we had taken time to contract it all out ourselves, the whole process would have taken way longer,” Smith said. “We were very satisfied with the way Egan took the bull by the horns and kept everyone in the loop, including the School Board.”

“The best part about my job is getting the opportunity to work with so many great people on the job sites.”

“The best part about my job is getting the opportunity to work with so many great people on the job sites.”

As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site.

As a customer for nearly 10 years, Mound-Westonka Schools rely on Egan Company for a number of maintenance needs, including boiler tune-ups and electrical outages. In summer 2016, Mound-Westonka High School had suddenly lost power, and a member of the school’s facility management team noticed smoke in the building. As Egan regularly works on various schools in the District, Egan’s Service team was called to the site. arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem.

arrival of the utility company to disconnect the school from the utility grid so they could safely evaluate the problem. supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server.

supply, fiber optic cabling, and all the wiring in the tunnel had to be repaired. With a new transformer, more than 6,400 feet of cable was installed to reconnect the service entrance conductors to the main electrical switchgear. New fiber optic cabling was installed to regain access to the District server. With ever-evolving technology, it is essential for companies to provide employees the tools to improve and enhance skills. Egan Company has built a Technology Center to provide employees a way to grow skills and learn more about popular, and some new, systems used on Egan projects.

With ever-evolving technology, it is essential for companies to provide employees the tools to improve and enhance skills. Egan Company has built a Technology Center to provide employees a way to grow skills and learn more about popular, and some new, systems used on Egan projects. Empowering employees is the key to ensuring safety on all jobsites, and it’s something Egan Company takes to heart with its Safety Brings You Home program. The intention is to make any employee – from apprentice to field leader to project manager – feel comfortable speaking up when they see something risky or unsafe onsite or even in the office.

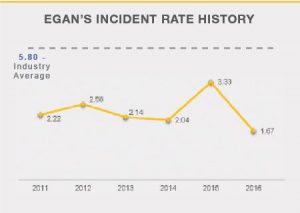

Empowering employees is the key to ensuring safety on all jobsites, and it’s something Egan Company takes to heart with its Safety Brings You Home program. The intention is to make any employee – from apprentice to field leader to project manager – feel comfortable speaking up when they see something risky or unsafe onsite or even in the office. Highlights of these efforts include:

Highlights of these efforts include: