During the month of November, Egan Company employees in the Twin Cities and Rochester volunteered their time at local food shelves to help families and organizations in need. Approximately 1 in 6 neighbors experience food insecurity in Minnesota, which includes 1 in 11 kids who don’t have regular access to the nutrition needed to thrive. These events sought to alleviate the stress and burden of a lack of access to food in our communities.

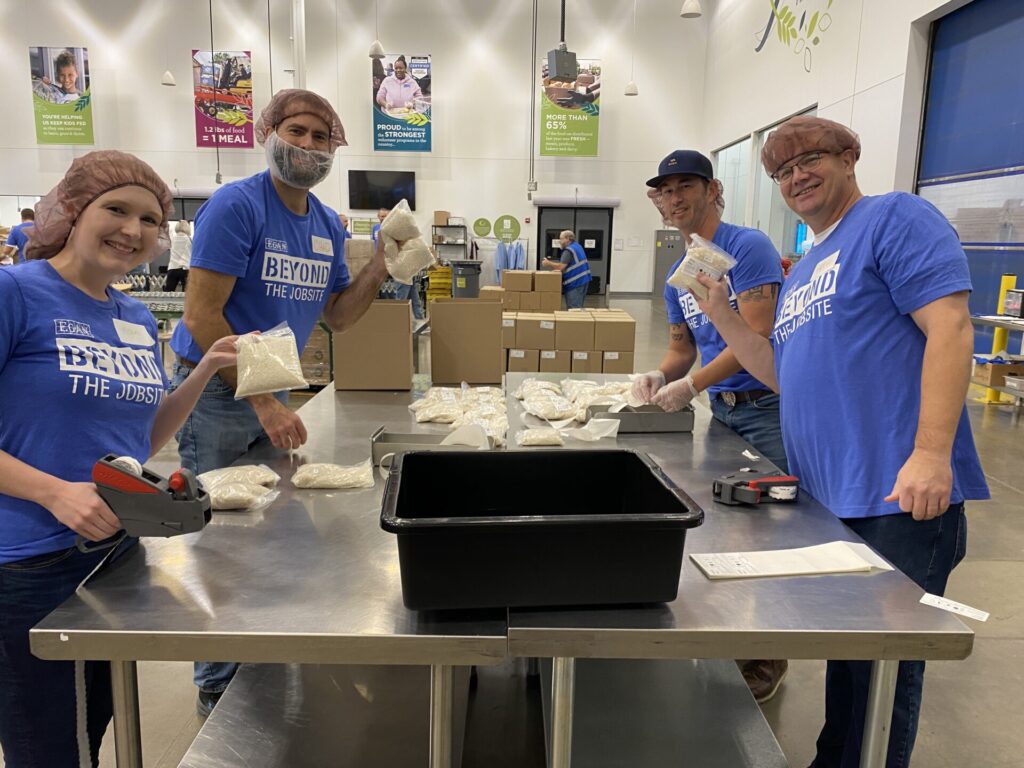

At Second Harvest Heartland in Brooklyn Park, 29 Egan employees volunteered to sort and pack food with members of the community. Second Harvest Heartland is an organization working to curb food insecurity and hunger in 59 counties throughout Minnesota and Wisconsin. The food bank collects donated and rescued foods in large quantities and distributes orders to individuals, families and local schools and other organizations. Second Harvest Heartland is an advocate on local, state, and federal levels to support communities and families.

The Southern Minnesota team volunteered in Rochester at Channel One Regional Food Bank on November 28. Channel One serves people experiencing hunger across 14 counties in southeastern Minnesota and western Wisconsin through food shelves, pantries, and programs. Last year, Channel One distributed 10,990,644 pounds of food to those facing food insecurity.

“I volunteered for the Second Harvest Heartland event because I believe in helping others and making a positive impact on my community,” said Jason Kellerhuis, Egan Company Senior Project Manager in the InterClad team. “It’s also a great way to learn new skills, meet new people, and make friends. Volunteering at this event or others like it is important for Egan Company and its employees because it reflects our core values and culture.”

Egan employees regularly stay involved with volunteering opportunities, including Bikes4Kids, Memorial Center blood drives, and making tie blankets. More information on our Community Involvement can be found here.