Creating a safe work environment takes more than a checklist. It takes people—engaged, committed, and looking out for one another. At Egan Company, safety is a leading core value, and during National Safety Month, it becomes the spotlight. This annual observance is a reminder to pause and refocus, not only on policies and protocols, but on the people they’re designed to protect.

Egan’s approach to safety extends beyond compliance. It’s built into the company culture and reinforced through daily decisions. Whether it’s a daily safety planning exercise or training, the focus remains the same: prevent injuries, protect each other, and ensure everyone gets home safely at the end of the day.

Building a Culture of Safety—Together

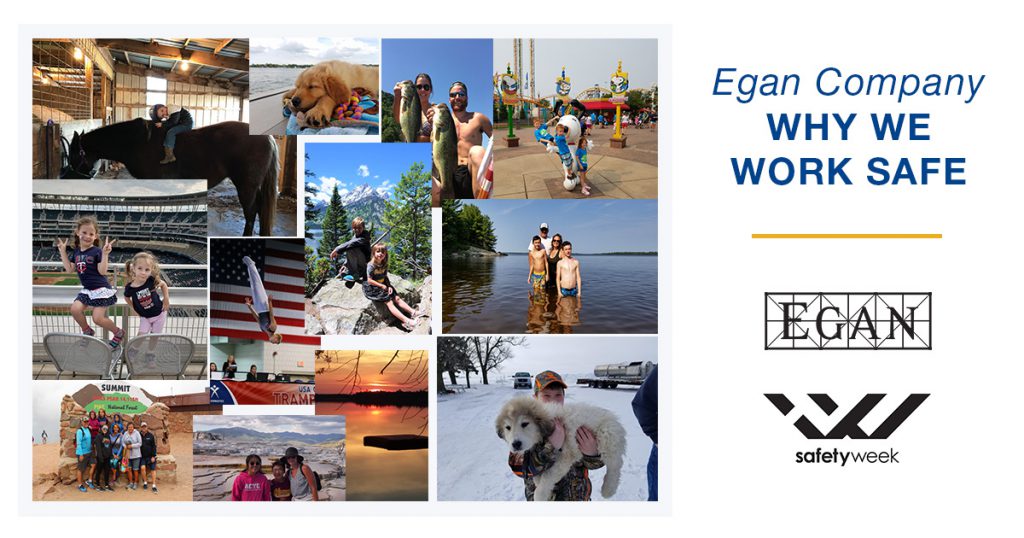

A strong safety culture is driven by shared responsibility. At Egan, that means encouraging every team member to speak up, ask questions, and offer solutions. In honor of National Safety Month’s “employee engagement” theme, Egan invited team members’ families to contribute their perspectives—with kids submitting safety-themed artwork that reminded everyone why we do this work in the first place. The message was clear: safety doesn’t stop at the jobsite. It impacts families, friends, and communities.

Keeping Our Guard up Outdoors

Outdoor Electrical projects present their own challenges—from moving equipment and changing weather conditions to limited visibility near roadways. That’s why Egan places special emphasis on outdoor safety, particularly when crews are working near traffic. Staying visible, alert, and protected with proper PPE isn’t just protocol—it’s essential.

Wellbeing Is Part of the Plan

Physical safety is only one part of the equation. Mental and emotional wellbeing are equally important. Recognizing this, Egan promotes resources that support the whole person—from hydration and rest to stress management and mental health tools. A well-supported team is a safer team.

In May, Egan observed Mental Health Awareness Month by sharing practical tools, resources, and reminders to prioritize mental wellness. That message carries directly into National Safety Month, reinforcing the idea that safety isn’t just about avoiding injuries—it’s about protecting the people behind the helmets and high-vis vests, in every sense of the word.

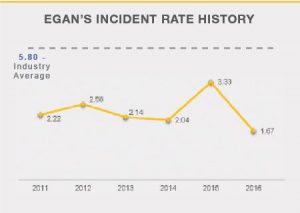

As one of America’s Safest Companies, Egan continues to uphold its reputation by cultivating a culture that places safety and wellbeing at the forefront. This recognition reflects not just past achievements, but a continued commitment to improvement, accountability, and the belief that every person deserves to work in a safe and supportive environment. National Safety Month may happen once a year, but at Egan, the commitment to safety is constant. The goal is always the same: continuous improvement, zero injuries, and a workplace where safety isn’t just expected—it’s embraced. By listening, engaging, and supporting one another, Egan continues to build a culture that protects people, supports wellbeing, and raises the bar for what it means to work safely. Want to see what safety looks like in action? Check out how the Egan team celebrated Safety Month across the company by following us on Facebook and LinkedIn.

Empowering employees is the key to ensuring safety on all jobsites, and it’s something Egan Company takes to heart with its Safety Brings You Home program. The intention is to make any employee – from apprentice to field leader to project manager – feel comfortable speaking up when they see something risky or unsafe onsite or even in the office.

Empowering employees is the key to ensuring safety on all jobsites, and it’s something Egan Company takes to heart with its Safety Brings You Home program. The intention is to make any employee – from apprentice to field leader to project manager – feel comfortable speaking up when they see something risky or unsafe onsite or even in the office. Highlights of these efforts include:

Highlights of these efforts include: