School districts are always looking for new ways to improve the safety, security, and comfort of the buildings for students and staff. Building technology integration plays a crucial role in creating a safe and engaging learning environment. With new technologies and building automation upgrades, schools can plan ahead for the safety and quality of their building for students and staff for years to come.

FIRE/LIFE SAFETY SYSTEMS

Fire alarm and life safety systems are essential for fire detection and life safety needs throughout school buildings. Auditing and reviewing these systems every 10 years or so is important to ensure they are meeting your facility’s needs and you are utilizing the latest technology available to keep your schools safe. Intelligent fire alarm control panels provide early warning capabilities, allowing for quick response and evacuation during emergencies. With features such as easy-to-use panels, mass notification systems, and graphical user interfaces, schools can ensure the highest level of safety for students and staff.

SECURITY TECHNOLOGY

Advanced security systems, including video surveillance, intrusion systems, and access control, can help monitor and control access to school premises. This building technology can integrate into existing systems, or schools can undergo complete security upgrades during the summer. Integrating these technologies can further improve the safety of schools by connecting to lockdown systems and access control technology for emergencies. Many schools are implementing additional access control measures, including badging, visitor management, mobile credentials, and building lockdown integration with these systems. Individual classrooms as well as entire wings of a campus can have access control measures, keeping every student safe wherever they may be.

COMMUNICATION SYSTEMS

Effective communication is vital in schools. Robust communication systems, such as intercoms and public address systems, enable clear and efficient communication within the premises. Connecting these communication systems with electronic message boards, monitors, and other mass notification systems is an effective way to distribute messages throughout the school or campus, whether you’re trying to contact an individual classroom or the entire building at once. Moving from analog to digital communication systems can more effectively reach students and faculty during lockdowns, weather events, school announcements, and other communications needs.

BUILDING AUTOMATION

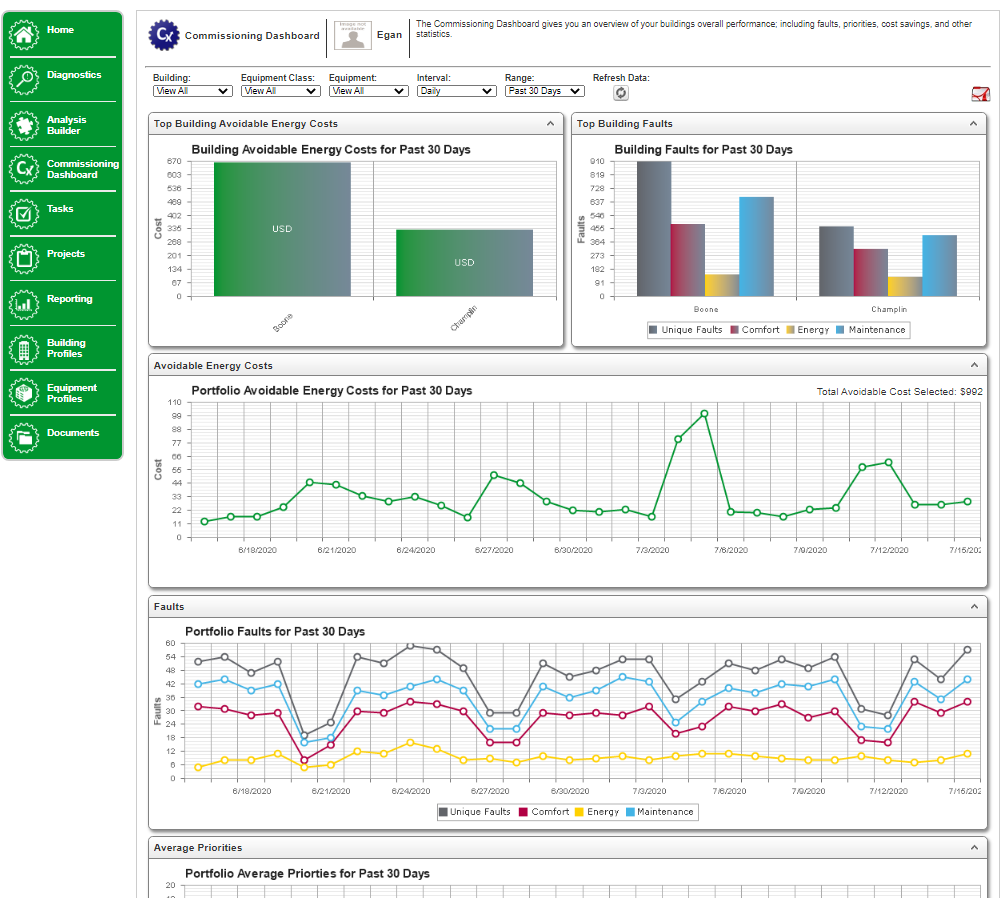

Building automation systems allow schools to have greater control and efficiency over their lighting and HVAC systems, leading to cost effective solutions and comfortable classroom environments all year round. A building automation system integrates smart technology to optimize the usage of lights, heating, and cooling systems throughout the entire school, including individual classrooms. Setting up these systems to operate based on occupancy in a room can reduce operating costs, improve the longevity of the equipment, and assist in your decarbonization initiatives. By utilizing a building automation system throughout each building, school districts can maximize the efficiency, cost, and comfort of running the building, whether it is during peak school hours or the downtime months during summer.

UPGRADE YOUR SCHOOL

As schools strive to create safe and conducive learning environments, building technology integration becomes increasingly more important. By integrating the latest technologies into buildings, school districts can enhance the safety, security, and overall functionality of educational institutions. Considering upgrades in the near future? Contact Egan Company’s Automation and Technology team to learn how you can benefit from new technologies.

With ever-evolving technology, it is essential for companies to provide employees the tools to improve and enhance skills. Egan Company has built a Technology Center to provide employees a way to grow skills and learn more about popular, and some new, systems used on Egan projects.

With ever-evolving technology, it is essential for companies to provide employees the tools to improve and enhance skills. Egan Company has built a Technology Center to provide employees a way to grow skills and learn more about popular, and some new, systems used on Egan projects. As the popularity of smart building technology increases, Egan Company continually strives to provide customers new and innovative ways to implement this technology in their facilities. Due to this commitment to innovation, Egan was chosen as a

As the popularity of smart building technology increases, Egan Company continually strives to provide customers new and innovative ways to implement this technology in their facilities. Due to this commitment to innovation, Egan was chosen as a  The OnGuard line of products is a natural fit for Egan and its

The OnGuard line of products is a natural fit for Egan and its