Fabrication: the name of the game when it comes to meeting deadlines and budgets and improving control over the supply chain. Egan Company’s state-of-the-art shops staffed by skilled tradespeople fabricate piping, plumbing, electrical components, panels, curtainwall, and metal panels.

Prefabrication projects are completed within our local shops with access to the necessary resources on demand. Our investment in continually improving the process is evident through preconstruction planning and feeding virtual construction plans directly into the fabrication equipment – both of which improve quality and save our customers time and money.

Fabrication capabilities include:

Plumbing and piping – A variety of deliverable products depart from our mechanical shop. When it comes to plumbing and piping systems, this includes everything from tube and pipe to hangers/supports. Modular custom-built systems are also at play in this fabrication shop to meet customers needs.

UL 508A panels – Our panel team creates custom control panels, designed and built in house. With precision assembly we configure panels of all shapes and sizes in our 12,000 square-foot panel shop. Shop features include: Steinhauer ModCenter (automated hole/cutout machine for enclosures), custom label manufacturing, OEM manufacturing, 6S methodology.

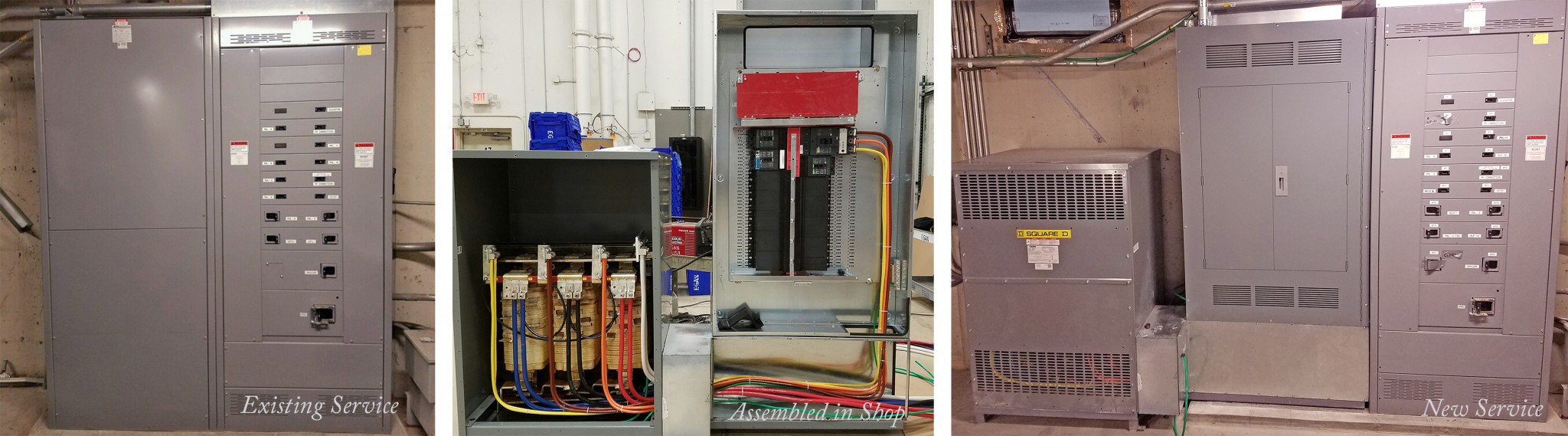

Electrical – Our design and virtual electrical teams map out projects virtually before they move on to be built in our shop and installed on site.

Curtainwall and metal panels – The InterClad team is able to fast track their curtainwall and panel projects with in-house drafting and engineering, matched with fast fabrication and assembly in their shop. The new addition of a CNC machine furthers the efficiency of this shop.

Working with Egan allows fabrication with no bounds – our capabilities will streamline your project to completion. The benefits of prefabricating your project are endless:

- Work is simplified and standardized

- Easier trade coordination with reduced task durations

- Increased quality of product

- Reduced crew on the jobsite

- Reduced deliveries and storage required on-site

- Reduced wasted materials

- Lower overall cost

- Increased safety in controlled environment

Check out one of our recent prefabricated projects.