The people, processes, and culture at Egan will forever have benefitted thanks to the investment and work put in by Mark Broadwater, Vice President of Automation, Technology, and Service and Brian Harren, Vice President of Electrical Solutions and Prefabrication. With a combined 58 years of industry experience, and 23 combined years at Egan, Broadwater and Harren are hanging up their hats and preparing for retirement in January 2026.

Putting People First: Mark Broadwater

Growth by way of relationships and people has led Mark Broadwater through his career; having humbly taken on any role necessary to support the companies where he’s worked, he has a strong appreciation for the team around him and what they need to be successful. Before he started his career as a limited energy installer at All Systems Company in Rochester, Minn., he was a people-oriented, athletic student who struggled in school due to dyslexia. While realizing academics were not a strength, his ability to influence a room and put himself out there when the time called for it came naturally.

Broadwater entered the industry when data and technology were booming, and he recognized the opportunity in front of him. He sought new opportunities to say “yes” to different roles, stepping in and stepping up when called upon. When All Systems was acquired, Broadwater took a contractual 18-month sabbatical. The day it expired, the then-CEO of Egan, Duane Hendricks, called Broadwater to offer him a position and help revive the culture within a quickly-growing business unit. “I remember telling Duane that what I’m good at is people. Not data or numbers or anything like that,” said Broadwater. “Every place has good people.” Thus, Broadwater’s tenure at Egan began.

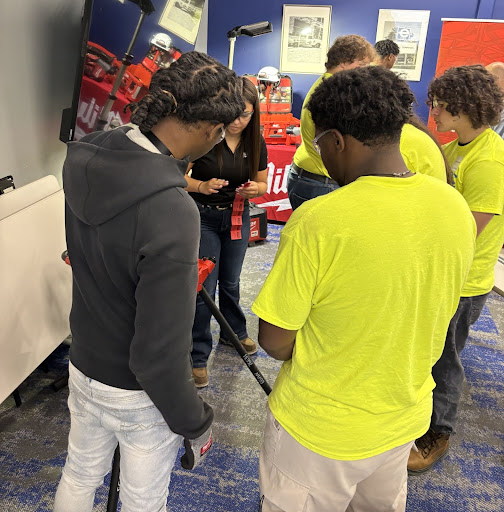

By taking a look at the structure and processes in place in this business, Broadwater sought to reignite the team. It was around this time that Egan repositioned its internal groups, placing Industrial Controls into its own operating group while Automation, Technology, and Service (ATS) stayed together. As the ATS business continued to grow and thrive, Broadwater turned his attention to the team; his goal was to grow the business and industry through its people. In his time at Egan, he saw a shift in culture, increased trust and camaraderie among employees, and a focus on families and life outside of the office. These efforts were exemplified during Egan’s first-ever Introduction to the Trades Day in 2025, hosting 30 elementary school children of Egan employees. “For something to be a passion of mine and then see it on our strategic plan, have my colleagues support it, and a wonderful team come together to create it has been one of the highlights in my career and my time at Egan,” said Broadwater. Reflecting on his career at Egan and beyond, Broadwater said humbly, “any success I’ve had is on the shoulders of others.”

Pay Attention to Everything: Brian Harren

Growing up with a persistent interest in electronics and how things worked, Brian Harren knew the kind of career he wanted to pursue. He enlisted in the Army after high school where he worked on missiles for three years. After that, he received a technology degree from Northwestern Electronics Institute (now Dunwoody College of Technology) and went to work doing production and installation for a material testing company. When he later made a career move to the water/wastewater industry, he found the opportunity to take on an engineering management role and expand his knowledge.

It was in this field that Harren started to adopt the mindset he’d take with him for the rest of his career: “I learned to pay attention to everything” Harren said. He sought to absorb everything, engaging with those around him, and making a difference wherever he could. “Everyone has strengths,” he said. “Leaning on the team to help solve problems is what makes an organization successful.” Harren began to take on a new approach to his work as he began to step into leadership roles: “Never lose sight of the vision,” he explained. “When someone comes to you with a problem, an idea, anything, dissect it to find the root of it! Being able to cut through noise and find ways to establish consistency, predictability, and better ways of doing things will lead your team to their goals.” Harren continued to pay attention to those around him, discovering opportunities to make adjustments and improvements in his teams, as well as within himself.

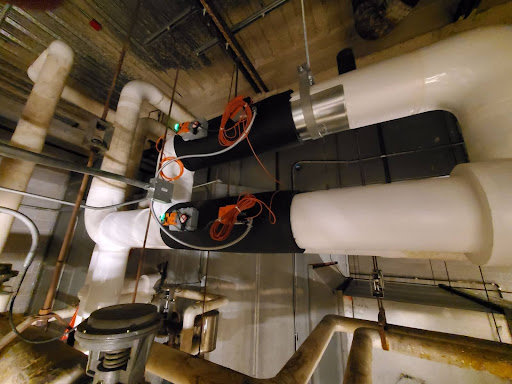

When Harren found his way to Egan in 2011 as the Industrial Controls Engineering Manager, he had a big challenge ahead of him. “It was a huge shift from working in a singular industry to multiple industries that Egan serves.” Once again, Harren found himself immersing himself in Egan’s industrial controls engineering group, learning and making connections, setting the vision and sticking to it, making necessary adjustments along the way. With what he describes as “the good people all around him,” Harren was asked to take on a leadership role within Egan’s Electrical Solutions and Prefabrication team, carrying over the “pay attention to everything” mentality, continuing to guide the people who make it all possible. In this role, Harren has helped reinvigorate Egan’s electrical prefabrication team, bolstered the engineering and virtual design/BIM technologies, and has guided the organization toward the future of electrical construction. Today, this operating group consists of 45 employees, including many in Egan’s Electrical Prefabrication shop in Kasson, Minn. The team continues to find efficiencies, integrate new technologies, and improve the way many processes are run.

Proud of the Past. Hopeful for the Future.

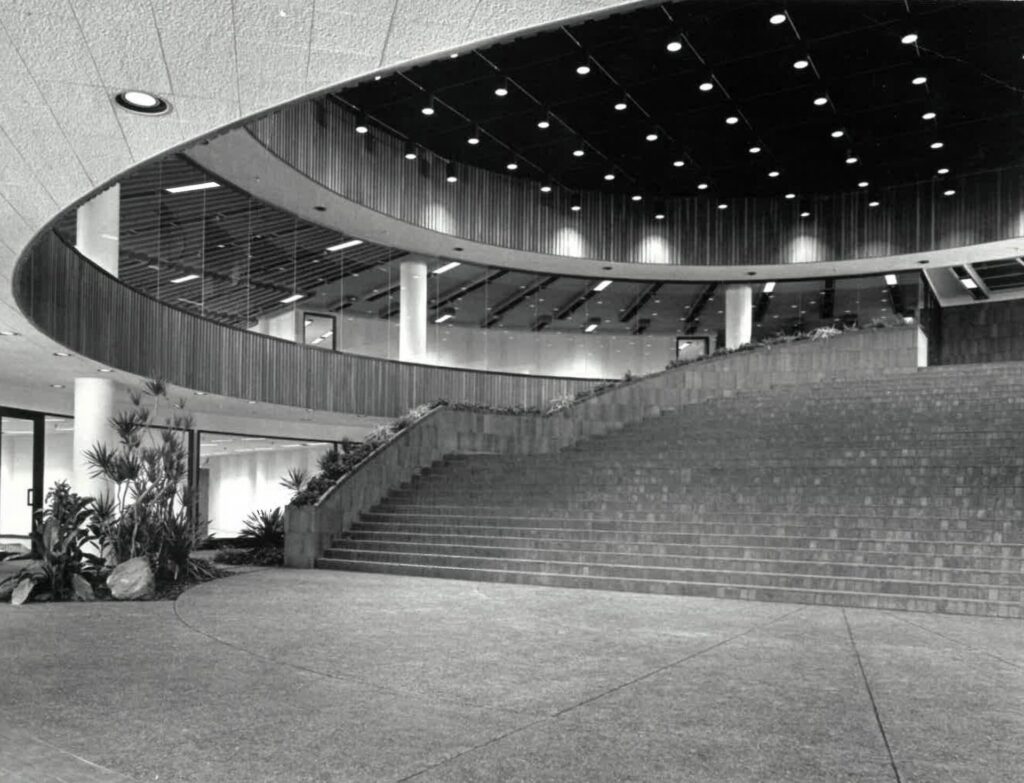

Broadwater’s and Harren’s legacies are ones where impacts will be felt for years to come. They each have had a hand in some of Egan’s most impactful projects, including Project Black Bear in Maple Grove, the FedEx Distribution Center in Rosemount, Egan’s Electrical Prefabrication facility in Kasson, as well as numerous facility upgrades for General Mills, Cargill, and other major manufacturers in Minnesota. Internally, they both contributed to growing their respective teams, establishing processes, and building up the people around them.

Each noted how the culture shift during their time at Egan was significant, and for the better. The people-first culture helped bring the company into the future, making way for innovation, collaboration, and safety. Both have their own personal mottos that have guided them in their careers, exemplifying Egan’s focus on the people: “Know People, or No People,” says Harren. “Knowing the people you work with and understanding their strengths and weaknesses allows you to effectively work with them. When you are aware of their strong points, you can let them work independently and thrive in those areas. When they need to stretch into an area of weakness, you can provide the support they need to succeed. Without knowing this, you are both eventually destined to fail.” Investing in each other, sharing ideas, and promoting the success of those around him were key to his own career and the success of the company. Broadwater’s outlook can be summed up in three short sentences: “Love first. Pursue people and relationships. Seek joy in everything.” By establishing trust among teams, creating cohesive business practices, and putting proper support and resources in place, Broadwater firmly believes that Egan has the greatest staff in the industry.

As for their personal futures, Broadwater is looking forward to his daughter’s upcoming wedding, traveling and hiking with his wife, being present with his parents, and spending time in the mountains out west. Harren intends to spend time with his family, including his five grandchildren, as well as golf, fish, volunteer, and simply enjoy retirement.

Each is confident that Egan is in good hands. “Someone will pick up the torch and carry it,” said Harren. The work they have both put in, not only in their time at Egan but over their entire careers, will leave a legacy that will be carried out by the next generation of industry leaders. Reflecting on the past, both Broadwater and Harren are humbly proud, as well as eager to take the next step into their futures.