Access granted: a front-row seat to the minds behind Egan Company’s security and access control solutions. We recently sat down with Bill Desmond, Operations Manager of Fire and Security, Kurt Johnson, Director of Sales and Ben Jahnz, Account Manager to talk specifically about what sets Egan apart in the world of security, access control, and integrated systems. It’s not every day you get to talk to the experts who’ve watched the industry evolve from keypads and doorbells to AI-driven, cloud-based systems with multi-layered authentication.

From Widgets to What-Ifs

Egan’s approach? It’s not about pushing a product. It’s about solving a problem.“We’re not here to sell a widget,” said Jahnz. “We want to understand what’s keeping our customers up at night. Then we build a solution that fits their unique situation.” That might mean navigating legacy hardware, integrating cloud systems, or even creating a completely customized setup. No two jobs are the same—because no two buildings, customers, or compliance requirements are the same.

“Getting from Point A to Point B depends on the day, the time, even the weather,” said Johnson, utilizing his favorite analogy. “Security’s the same way. There are a hundred routes to a single solution—and we help the customer find the one that fits.”

Built on Relationships (Not Just Hardware)

The team emphasized that Egan’s difference lies in its partnerships—whether that’s with the customer or the manufacturer. While some integrators avoid looping in manufacturers, Egan brings them to the table. “If we don’t know something, we don’t pretend we do,” said Johnson. “We bring in the experts to help our customers make the best decisions.”

That transparency builds trust—and it’s led to winning projects even when Egan wasn’t the lowest bid, because the value of collaboration speaks for itself.

Compliance, Complexity, and Cloud

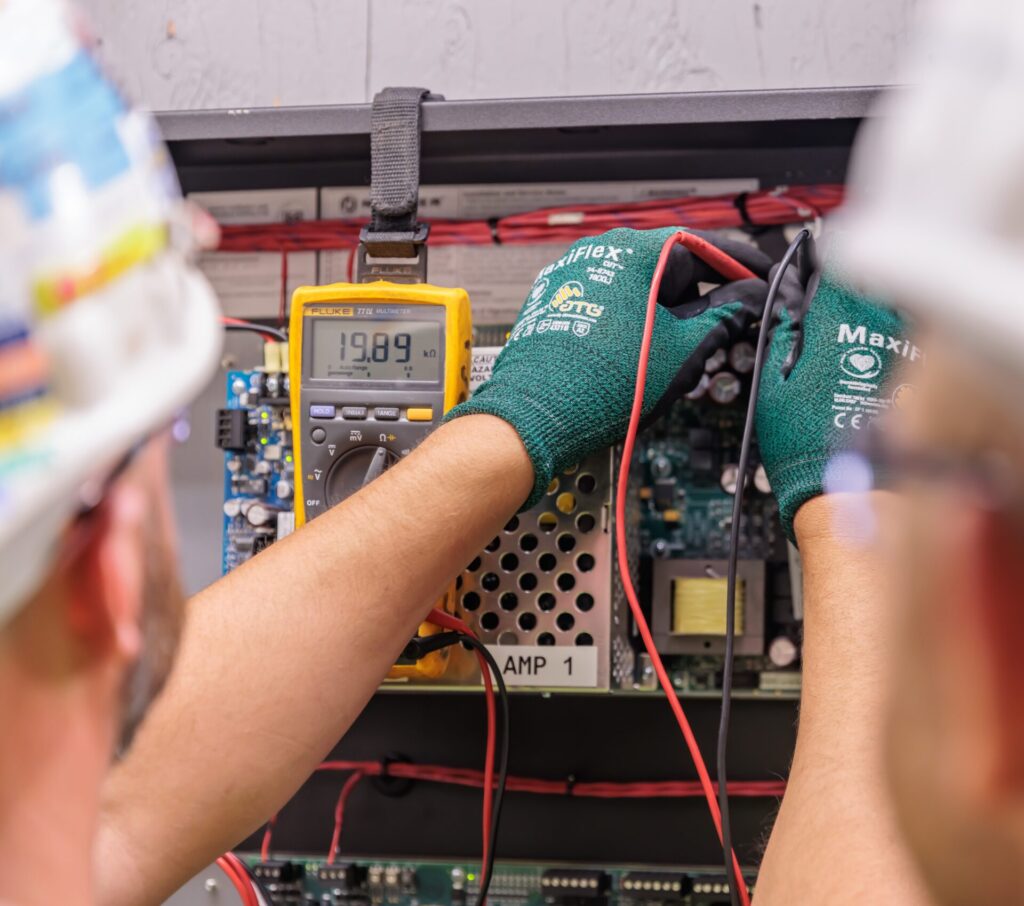

The team also shared how Egan keeps up with ever-changing compliance codes, data privacy standards, and customer-specific needs—especially across industries like healthcare, manufacturing, education, and municipalities. From high-security server rooms to school doors that need to open only for the right badge, the stakes are high and the complexity is real. Yet not all providers see it through. “We’ve walked into sites where systems were installed by another company and then just…left it to the building owners to know what to do,” said Jahnz. “There was no documentation, no training, no follow-up—just wires, hardware, and confusion. We fix those, maintain them, and keep them running. That’s a big part of our service philosophy.” At Egan, it’s not just about installation—it’s about long-term support, clarity, and doing the job right the first time and every time after.”

Empowering Through Education

One standout takeaway? Egan’s commitment to teaching customers—not gatekeeping knowledge. “We’re not here to protect my job by withholding information,” said Desmond. “We want our customers to know how to use their systems—and fix simple things on their own if they want to.” That mindset isn’t just rare—it’s powerful. It turns a service call into a relationship and builds trust that lasts long after install day.

Desmond added, “We’re not just the installer. We’re the partner—before, during, and long after the project is done. Our goal is to make sure the system works for the customer, not just the day we leave, but every day after.” That long-term perspective reinforces Egan’s commitment to transparency, reliability, and ongoing support.

Looking Ahead: AI, Video Analytics & Proactive Solutions

AI isn’t something Egan fears—it’s something already in use. From early smoke and heat detection to license plate recognition and intelligent video analytics, the future is already here. “Tech like this used to be a cool idea,” said Johnson. “Now, it works.” And the best part? You don’t need a master’s degree in programming to use it. Many systems are becoming more user-friendly, empowering facility teams and end-users to do more—with confidence.

Bottom line? Security isn’t a one-size-fits-all scenario—and Egan isn’t a one-size-fits-all team. Whether it’s a factory floor, a hospital wing, or a city-wide surveillance system, Egan is building smarter, safer spaces with the right mix of tech, trust, and teamwork. Ready to build a better security solution? Contact the Egan team today to start the conversation.