Spring cleaning season is here. For commercial properties, this may look different than raking the yard and emptying the cupboards, but it is equally as important. Taking stock of the condition of commercial equipment is key for ensuring everything is operating the way it should. This is the time of year when mechanical experts and boiler technicians come to life, springing into action to get commercial heating and process equipment in tip-top shape.

Boiler teardowns typically occur in the spring, as a form of preventative maintenance that keeps the equipment operating at maximum efficiency. By planning ahead and tuning up your equipment, your commercial boilers and burners will be ready to go when you need it most.

WHAT IS A BOILER TEARDOWN?

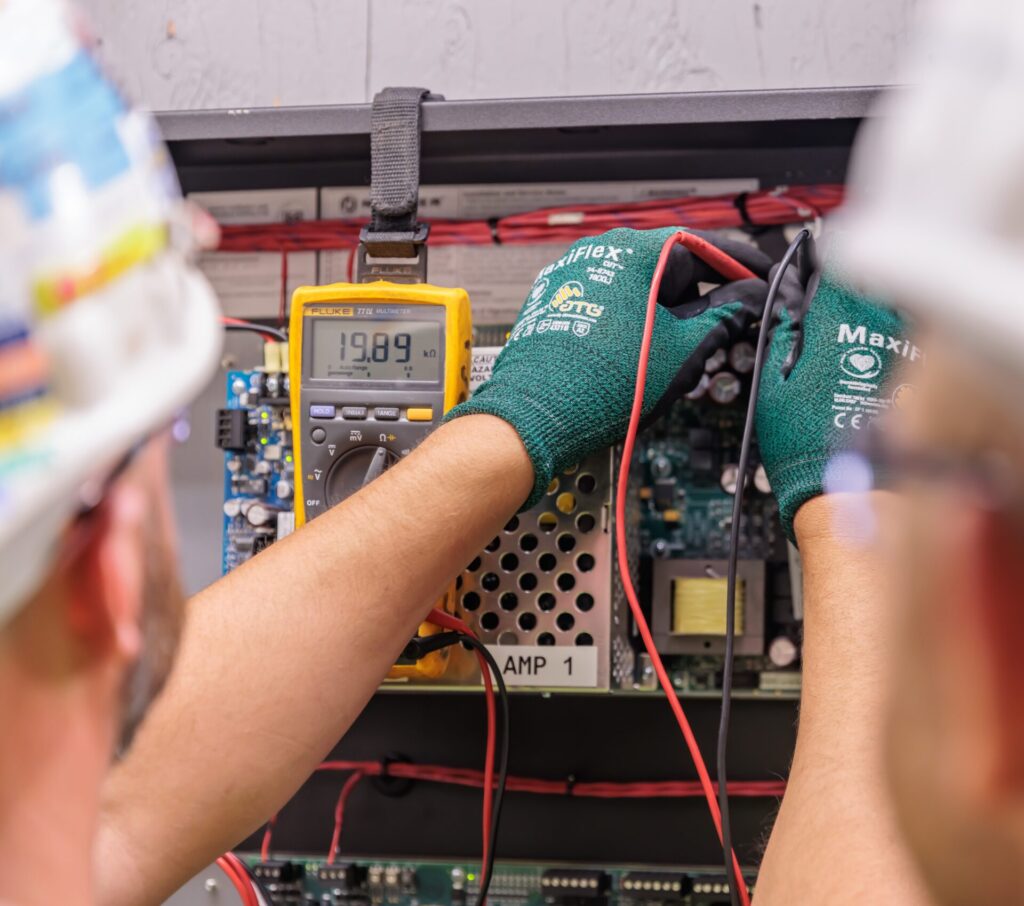

During a teardown, a boiler technician will disassemble the equipment in order to fully inspect, clean, and conduct necessary service and repairs. While the equipment is decommissioned, technicians “punch” the tubing, cleaning out accumulated soot and debris, maximizing efficiency so your heat, water, and industrial processes are running smoothly.

Commercial and industrial heating boilers see heavy demand throughout the winter in Minnesota, which can lead to wear and tear over time. Large-scale process boilers and domestic hot water equipment are often used year-round, making regular shutdowns and tune-ups even more important. A full boiler assessment can identify potential corrosion, damage, or other issues before they become too serious.

GETTING AHEAD WITH PREVENTATIVE MAINTENANCE

Setting a schedule for boiler teardowns ensures that maintenance and system cleaning isn’t missed. Depending on the use of the equipment, whether it is used year-round or just in the winter, the boilers and burners should be cleaned regularly, once or even twice a year. Egan Company’s Service team can track your service history and help make sure you don’t miss necessary maintenance.

Additionally, curtailment rules go into effect in the fall and winter in Minnesota, meaning commercial properties who run Dual Fuel burner systems need to be ready to switch their equipment over to alternative heating methods with short notice. This becomes difficult without proper maintenance and preparation. It all comes down to keeping your building systems working properly, while keeping your operating costs low.

READY, SET, HEAT

Getting ahead of maintenance now can make everything much easier when it’s time to fire up your commercial boilers. The Egan advantage means having a partner for your facility who thinks ahead and looks out for your building and equipment, whether you are running heating equipment, domestic hot water, or industrial process boilers. Our dedicated commercial boiler and burner experts focus on the details of what your equipment needs to perform when it matters most, so you can focus on running your business. Get in touch with our team to learn how we can help conduct boiler teardowns and preventative maintenance for your facility.