With winter right around the corner, commercial boilers will start to heat up. Without proper maintenance, testing, and inspections, the equipment risks shutting down when it’s needed most, leaving facility managers and building owners left in the cold. Scheduling preventative boiler check-ups is key to keeping your facility warm, your tenants happy, and your equipment compliant.

How to Get Ready for Winter Boiler Season

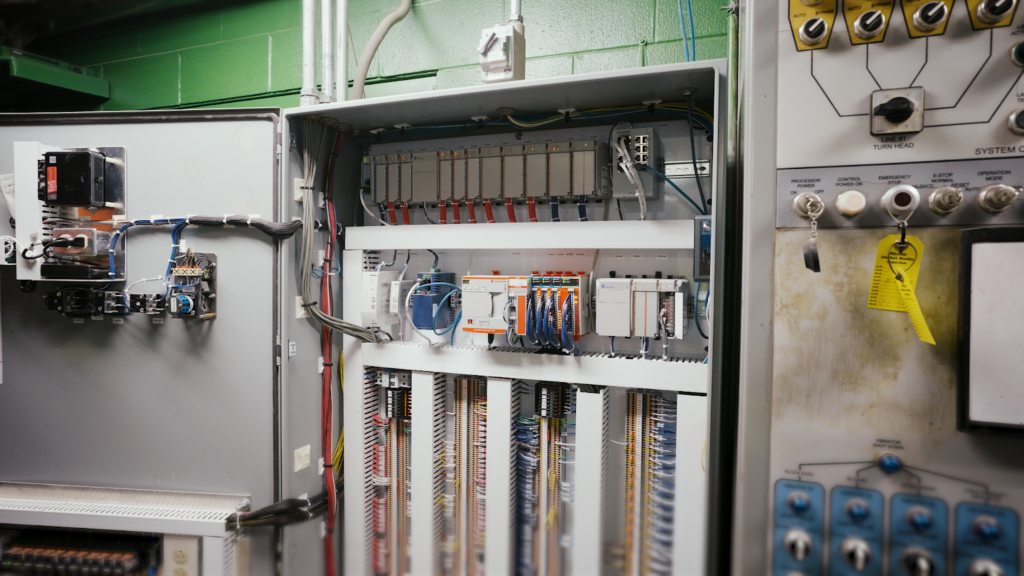

Preparing for winter ahead of time can save a lot of money and stress when it’s time to turn on commercial and industrial boilers. In addition to meeting requirements set by the state of Minnesota and many insurance companies, proper boiler inspections help make sure buildings are comfortable and safe during the coldest months of the year. Preventative maintenance and boiler start-ups typically include certified boiler technicians opening up and cleaning the equipment (if it was not done in the spring), and then closing up and testing the boilers. This process ensures that the boilers and burners in commercial facilities are ready for increased demand, and can reduce the need for emergency repairs when winter rolls around.

Prepare for Boiler Curtailment

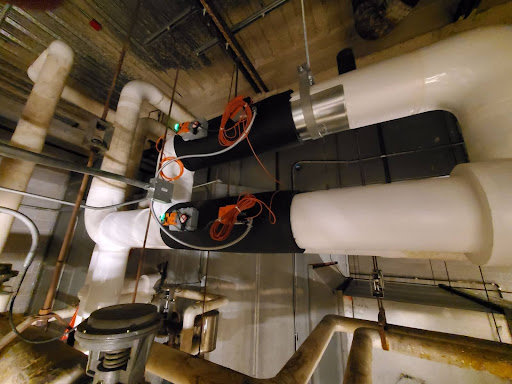

For commercial & industrial facilities using dual fuel boiler systems, curtailment is a critical aspect of winter heating that needs to be taken into consideration every year. As determined by the State of Minnesota, boiler curtailment reduces or adjusts energy consumption during peak heating demand. On particularly cold days, facilities running dual fuel boiler systems are notified that they must switch to their alternative fuel sources within a set amount of time, helping to allocate resources to heating systems that require natural gas.

Proper preventative maintenance and inspections enable easy switching at a moment’s notice; without preparation, dual fuel equipment may not be able to switch to alternative fuel systems, which may result in fines from local utilities.

Looking Out for Your Facility

Proactive maintenance and equipment check-ups are important for all facilities. As winter nears, now is the time to think about heating systems, curtailment rules, and inspection requirements. In addition to properly working equipment plus state and insurance requirements, boiler inspections can come with rebates, as well. CenterPoint Energy offers rebates every other year for commercial facilities when they complete their annual boiler inspection. Egan Company’s team of boiler experts and certified boiler technicians are trained to work on equipment of all types, and can help keep your building running smoothly. Get ahead of winter heating requirements and schedule boiler equipment maintenance, and melt the winter blues away.