Witnessing the payoff of a 40-year career is a rare honor, achieved by those who navigate industry shifts and business growth with unwavering dedication. It takes a committed individual to hold true to their values, adapt to change, and leave a lasting impact.

Mike Tengwall, Egan Company’s Senior Vice President of Electrical, embodies this journey. Throughout his career, he has continuously evolved to meet the demands of the industry, driven by a strong work ethic and a commitment to integrity. From starting as an electronics technician to becoming an apprentice at Klatt Electric in Buffalo, MN, Tengwall rose through the ranks—from Class A Master Electrician to project manager, to group manager, and eventually to Senior Vice President and Director on Egan’s Board. Now, as he prepares to conclude four decades of leadership, his legacy of teamwork and impact is undeniable.

TEAM OVER SELF

Tengwall’s success has always been rooted in collaboration. As a project manager, he worked closely with customers and electricians to ensure facilities operated as intended. His leadership approach remained consistent as he advanced to Business Group Leader of Egan’s Industrial Controls team and later to Senior Vice President of Electrical.

“It’s not about us individually, but as a collective team,” Tengwall said. By placing trust in his teams and providing the support they needed, he played a vital role in the growth and success of Egan’s electrical business over the past 17 years.

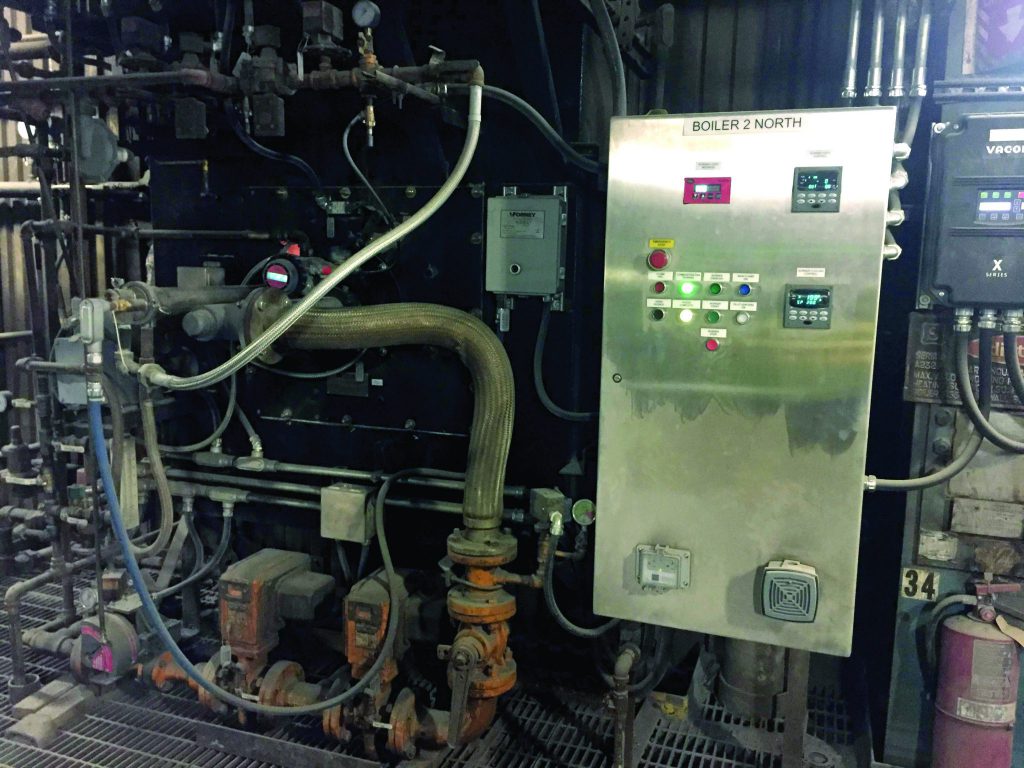

Throughout his time with Egan, Tengwall contributed to numerous significant projects in food processing, manufacturing, and industrial and commercial sectors. His broad project experience gave him a unique perspective, driving his commitment to asking questions, digging deeper, and fully engaging with each job.

His curiosity often translated into a forward-thinking mindset, embracing new technologies and innovations to empower his team. “If we don’t change and evolve, we won’t remain viable,” Tengwall noted. “We need to keep up with the industry, using data to drive improvements and progress.”

This mindset contributed to the growth of Egan’s Electrical business group, and that growth shows no signs of slowing.

SETTING UP FOR SUCCESS

Whether collaborating with customers, building managers, or electricians, Tengwall maintained a consistent approach. He believed the key to success in the industry was to “stay motivated, work hard, and do what’s right, no matter what.”

This mindset has spread throughout Egan, laying a solid foundation for the company’s future as it continues to adapt to the evolving industry. Tengwall’s openness to change and technology ensured the company’s viability. “Change happens,” Tengwall shared. “Finding ways to be efficient with technology is what keeps you competitive in this industry.”

LOOKING AHEAD

As Tengwall prepares to step down, he leaves Egan’s Electrical team in a strong position. Confident in the team’s ability to continue thriving, he encourages patience and curiosity. “Be patient; things don’t happen overnight. Focus on the big picture and give your people the opportunity to succeed. Constant, steady pressure is the key to achieving goals and navigating change.”

Grant Price, who has spent the last 22 years in leadership roles within Egan’s Industrial Controls team, will take over as Senior Vice President of Electrical, having most recently served as Vice President.

As for Tengwall, he is looking forward to a well-earned retirement, joking that he plans to “stop setting his alarm clock” and spend time with his family, including his wife, three daughters, and nine grandchildren. He and his wife are excited about upcoming travel plans, including trips to Florida and Costa Rica.

Reflecting on his time at Egan, Tengwall said, “It takes all of us, every day, to do what we do. I’ve been blessed to be part of a great team here at Egan.”

High-rise buildings are the distinguishing trademark of cities around the world. And, being the 16th largest metropolitan area in the country, Minneapolis and St. Paul are no different.

High-rise buildings are the distinguishing trademark of cities around the world. And, being the 16th largest metropolitan area in the country, Minneapolis and St. Paul are no different. The project was officially awarded to Egan by Bigos Management in late March. From the start, Egan’s team knew the new cooling towers would need to be “flown” up to the top of the building. To do the “flying”, Egan began coordinating and pre-planning with a local crane company, Vic’s Crane and Heavy Haul.

The project was officially awarded to Egan by Bigos Management in late March. From the start, Egan’s team knew the new cooling towers would need to be “flown” up to the top of the building. To do the “flying”, Egan began coordinating and pre-planning with a local crane company, Vic’s Crane and Heavy Haul. Although there was two feet of snow on the ground when the project started, Minnesota’s infamously, unpredictable spring weather found itself over 85 degrees just a few weeks later. With the previous cooling towers entirely off the building, the countdown was on to get the first new cooling tower operational in order to start cooling all of the buildings within the city block.

Although there was two feet of snow on the ground when the project started, Minnesota’s infamously, unpredictable spring weather found itself over 85 degrees just a few weeks later. With the previous cooling towers entirely off the building, the countdown was on to get the first new cooling tower operational in order to start cooling all of the buildings within the city block.