Whether it’s powering a high-rise, streamlining a hospital expansion, or ensuring round-the-clock performance at a mission-critical site, Egan Company’s electrical teams deliver more than just power—they bring strategic foresight, technical precision, and unmatched collaboration.

To uncover what truly sets Egan’s electrical services apart, we sat down with three key leaders: Grant Price, Senior Vice President of Electrical; Jason Rosati, Vice President of Electrical Special Projects; and Jason Brown, Electrical Business Group Manager. Together, they offered a comprehensive, behind-the-scenes look at how Egan’s electrical divisions work seamlessly to deliver industry-leading results across sectors.

A Full-Circuit Approach

“We’re not just wiring buildings,” Price shared. “We’re enabling businesses to operate more efficiently, safely, and reliably.” Egan’s electrical capabilities extend across multiple interconnected groups—including Industrial Controls, Outdoor Electrical, Electrical Special Projects, Electrical Construction, Southern MN, and teams dedicated to commercial and mission-critical builds. While scopes range between installing a single outlet and powering massive data centers, every group contributes to a broader, unified electrical offering.

“The goal is for customers to see the full picture,” said Rosati. “They might know we install lighting or build control panels, but it’s the coordination between our groups that truly unlocks more value.”

Whether it’s a power distribution and lighting system or low-voltage infrastructure and advanced control integration, there’s hardly a system Egan’s teams haven’t tackled. We design, build, and support a wide range of environments—corporate campuses, healthcare facilities, manufacturing plants, and more—all while adhering to strict safety standards like NFPA 70E, NFPA 70B, and energy code compliance.

Design Smarts Meet Jobsite Strategy

As the conversation shifted toward how Egan approaches Design/Assist and Design/Build projects, one principle became clear: partnership is everything. “We aim to get involved as early as possible,” said Brown. “The sooner we’re at the table, the better we can align expectations, navigate constraints, and help future-proof the system.”

The team detailed how they balance owner expectations with budget requirements—often drawing on their broad experience and internal resources to recommend long-lasting, cost-effective solutions. This includes participating in walkthroughs, interpreting vague narratives, and asking the right questions to ensure the delivered system meets performance needs. “Would you install it in your grandma’s house?” Rosati joked. “That’s our gut check.”

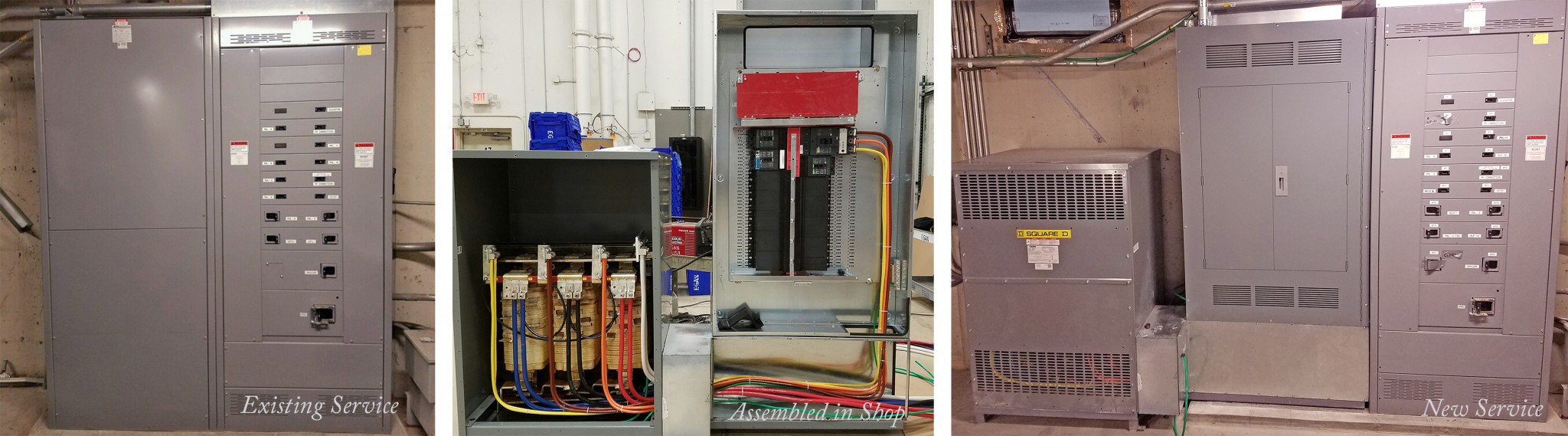

Prefab That Powers Productivity

Prefabrication is another area where Egan excels—especially when it comes to compressing timelines and enhancing safety. Whether it’s assembling conduit racks, underground duct banks, or room-in-a-box electrical kits, prefab ensures field teams can stay focused on installing, not assembling. “When prefab is done right, it accelerates everything,” Rosati emphasized. “Our jobsites are safer, cleaner, and more efficient. That’s what GCs and customers care about—and so do we.”

Staying Ahead of the Curve

Technology and sustainability trends continue to shape Egan’s work. Lighting controls, daylight harvesting, and all-electric buildings are becoming more common, especially as local and national codes evolve.

“We’re seeing the electrification of everything,” said Price. “We worked on a 400,000-square-foot research facility that runs completely on electricity—no gas. That kind of project is paving the way for what’s next.” Still, the team was quick to note that while sustainability is critical, they focus first on meeting requirements and delivering solutions that last. It’s about balance—not buzzwords.

Relationships that Matter

One often overlooked value-add for Egan customers? Strategic relationships—not just with vendors, but with a robust peer network across the country. Backed by preferred vendor certifications with trusted manufacturers like 3M and Rockwell Automation—and strengthened by long-standing partnerships with peer firms—Egan leverages an expansive network that brings tangible benefits to every project. These relationships aren’t just symbolic—they create real advantages in the field.

“These relationships mean faster procurement, better pricing, and access to specialized resources,” said Rosati. “They can be the difference between delay and delivery.”

Peer group connections, in particular, allow Egan to collaborate on best practices, stay ahead of market trends, and extend capabilities when needed.

One Team. One Electrical Story.

In wrapping up the conversation, the leaders circled back to a common challenge: telling the full story of Egan Electrical. “Customers—and even some internal folks—sometimes only see one piece of the puzzle,” said Price. “But when you zoom out, you realize how much we actually do.”

Whether it’s installing critical infrastructure or solving complex, no-shutdown electrical cutovers, Egan’s electrical group is built to support every stage of a building’s lifecycle—with one point of contact and a whole lot of capability behind it. After all, when it comes to electrical, there’s more to leverage.