In a world where facility managers face mounting pressures to do more with less—less energy, less downtime, and fewer resources—modern building automation systems offer an essential edge. From helping schools improve air quality to supporting high-performance dispatch centers, Egan Company’s Building Automation group is focused on delivering smarter, more responsive spaces.

We had the chance to sit down with Kirk Wahlstrom, Building Automation Group Manager, and Ryan Haller, Building Automation Engineering Manager, for a conversation about what it really takes to deliver smarter, more responsive buildings. At Egan, they focus on complex integrations and long-term system strategies that help keep facilities comfortable, efficient, and ready for what’s next. For them, it’s not just about cutting-edge technology—it’s about building relationships that last.

Delivering Comfort, Control, and Customization

Whether it’s a pharmaceutical plant, a K–12 school, or a government facility, the Building Automation team works behind the scenes to optimize how indoor environments function. Think of it as the industrial-grade version of a home thermostat—scaled across campuses and coordinated through interconnected systems of air, water, and energy controls.

Haller sums it up simply: “We don’t control the thing—we control the air around the thing.” The group is laser-focused on managing space comfort and critical environmental needs for both occupants and operations. At its core, the team’s work translates to increased efficiency, cost savings, and elevated comfort. But as Wahlstrom points out, that’s just the beginning. “We try to make the technology fun—to make it exciting for

customers to engage with their buildings in new ways.” Wahlstrom also believes in giving end users the confidence and control to operate their own systems. “I tell people our goal is that you do 90 percent of things with the system and your building—and we are just that small technical icing on the cake.”

Migration That Meets the Moment

Replacing outdated systems is often easier said than done. Legacy hardware—some installed 30 years ago—is still operational in many buildings today. But as manufacturers stop supporting old platforms, a proactive migration strategy becomes critical.

Instead of pushing a one-size-fits-all upgrade, the team tailors plans that align with a customer’s financial realities, whether through full capital projects or phased improvements. The goal: to move clients from reactive maintenance toward predictive performance. “Do you want to be broken down on the side of the road,” Haller asks, “or do you want to plan for a brake replacement ahead of time?”

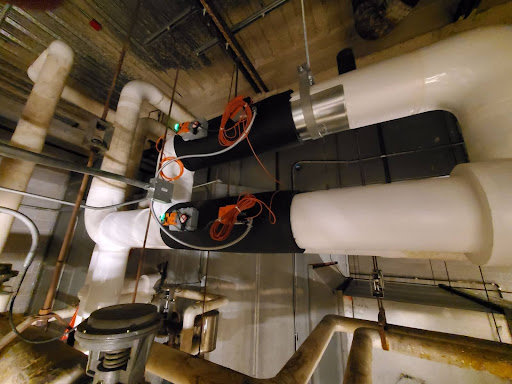

Recent projects like the multi-year system overhaul at Mystic Lake’s central plant or the complete modernization at Centennial Lakes Office Park show how Egan is helping customers bridge the gap between now and next.

Thinking Bigger With Building Data

Automation is evolving—and Egan is helping clients evolve with it. Leveraging data to identify inefficiencies and monitor performance is key to optimizing system operations.“We’re seeing more interest in fault detection diagnostics,” says Haller. “It’s about identifying issues before they become expensive problems, which leads to smarter decision-making.”

New tools like AI and machine learning are starting to influence how buildings are modeled and maintained. The challenge, however, is access to data at scale. While large cloud-based datasets can train predictive systems, most buildings today still lack the infrastructure to collect and leverage that information effectively.

That’s why Egan places heavy emphasis on designing networked systems that can scale—and why it partners closely with vendors and industry organizations to stay ahead of emerging trends.

Collaboration That Builds Confidence

Every building has its own challenges, and collaboration is critical to finding the right solution. As a third-tier contractor, Egan often works behind the scenes, interfacing with general contractors, engineers, and mechanical partners to bring a project’s vision to life.

“We strive to make sure that we’re not the fly in the ointment,” says Wahlstrom. “We try to make their lives as easy as possible by providing timely communication, timely execution, and minimal warranty callbacks.”

That commitment to seamless delivery extends beyond the install. Follow-up trainings, visits months after handoff, and system customization are part of what differentiates the Building Automation team. Stakeholders can count on more than technical execution—they can expect a collaborative partner who helps them own and optimize their systems.

Future-Proofing With Purpose

Whether it’s enabling remote monitoring, integrating nonproprietary controls, or simply offering the flexibility to evolve over time, the group’s focus is long-term scalability. Their advice for customers just starting their building automation journey? Start where the impact is highest—large-scale systems like boilers and chillers—and build out from there.

Keeping technology current is another area customers often overlook. “Getting a system upgraded after 30 years is a milestone,” says Wahlstrom, “but the truth is, technology moves so fast that staying current is now a continuous process.”

At Egan, delivering high-quality, tailored systems is more than a technical mission—it’s a cultural one. The Building Automation group stands behind its work, prioritizes customer needs, and refuses to settle for good enough. As Wahlstrom puts it, “we don’t walk away. Egan works to make sure we’re delivering something we’re proud of—and that the customer trusts.”