When it comes to building complex infrastructure, every detail matters—down to the precision of concrete batching. At Egan Company, IntelliBatch® is the software solution that keeps production running smoothly, consistently, and efficiently. Recently, we sat down with Jeremy Quam, Concrete Batch Operations Supervisor, and Matt Haan, Concrete Batch Project Manager, to learn more about how IntelliBatch helps plants gain control, minimize downtime, and maximize performance.

Meeting the Needs of Every Customer

No two plants are the same—and neither are their batching requirements. IntelliBatch is built and tailored for supporting precast, pipe, dry packaging, architectural, and hardscapes. “IntelliBatch is the front-end PC software that runs these systems,” Quam explained. “It’s the user interface that allows operators to control everything from a simple keyboard and mouse or touchscreen. Intellibatch adapts to nearly any configuration a customer needs.”

Safety is always central. “We can design systems from Category B all the way up to Category 4,” Haan shared. “That means using safety-rated components and approved programming methods that keep operators and equipment safe.”

Accuracy, Consistency, and Scale

To deliver accuracy and consistency, Egan follows a standardized process—from CAD and design to panel fabrication and programming. Some systems push limits, like Cambridge Pavers, where multiple mixers and destinations need to sync seamlessly. “It can be a complex process—but IntelliBatch makes it possible,” Haan noted.

Minimizing Downtime, Maximizing Output

For existing plants, downtime is the biggest concern. That’s why the team prefabricates panels in advance, runs factory acceptance testing, and creates crossover plans before arriving on site. “Our goal is always to minimize downtime,” Quam said. “As much fabrication as possible is done at our facility in advance so production is back online with minimal interruption.”

Data Integration with enterprise resource planning (ERP) systems like NetSuite is one of today’s biggest trends. “We continue to get more requests for ERP integration,” Haan explained. “We’ve developed APIs that let IntelliBatch share real-time data like material usage, recipes, and production data across multiple sites.”

Built to Last

Concrete batching plants operate in tough environments, but IntelliBatch is built to last. Many systems have been running for 15+ years, with backup processes in place to keep operations moving if a component fails. “Every night at midnight, IntelliBatch creates a backup,” Quam said. “If a PC ever goes down, customers can restore it to a new one in minutes and be running again.”

Every IntelliBatch system includes prefabricated panels built in Egan’s UL 508A Panel shop. Prior to leaving the shop floor, each system goes through a complete validation process—simulating the customer’s plant to mirror real-world conditions. “That preparation makes commissioning smoother,” Quam said. “When the system arrives on site, we are positioned to get the plant producing as quickly as possible.”

Delivering IntelliBatch systems requires tight coordination across Egan’s project managers, engineers, CAD designers, purchasing, and panel shop technicians. From schematic drawings to as-built documentation, every step is tracked to ensure seamless integration and a successful startup.

The commitment doesn’t end at commissioning. With dedicated project managers, account managers, and a concrete batching service line, customers have support for plant expansions, retrofits, or emergency needs long after the first batch is produced.

A Team Effort for Long-Term Success

Early planning is always critical. As Haan says, “That’s why communication and preparation make all the difference.”

The IntelliBatch team at Egan brings many disciplines together, from engineering and design to fabrication and service, to deliver systems that work the way they’re meant to—day one and years down the road. With these combined expertise, customers can count on a partner who truly understands their batching needs.

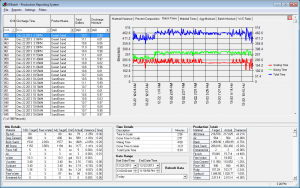

In concrete batching plants, accuracy and quality are the top priority. Comprehensive and informative quality control processes ensures that concrete facilities’ can provide customers with the safest and highest quality product possible.

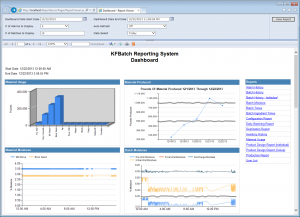

In concrete batching plants, accuracy and quality are the top priority. Comprehensive and informative quality control processes ensures that concrete facilities’ can provide customers with the safest and highest quality product possible.  This information is available on a customizable dashboard, allowing concrete facilities to reduce product waste, enforce strict quality standards, and quickly tie batches back to any recalled products.

This information is available on a customizable dashboard, allowing concrete facilities to reduce product waste, enforce strict quality standards, and quickly tie batches back to any recalled products. Secured, safe, efficient – deliver hassle-free remote connection to concrete batching systems with Egan Company’s newest product, EganConnect.

Secured, safe, efficient – deliver hassle-free remote connection to concrete batching systems with Egan Company’s newest product, EganConnect.