Maintaining optimal ice quality for indoor ice arenas requires reliable, consistent temperatures and maintenance. Outdated temperature controls compromise the quality and care of the rink, leading to uneven playing surfaces, temperatures that are difficult to manage, and undesirable conditions for skaters. From increased maintenance demands, ongoing repairs, and inconsistent performance, outdated refrigeration controls make ice arena management difficult and costly.

LACE UP: CUSTOM CONTROL DESIGNS

Before you can hop on the ice, you need skates that fit. The same goes for the refrigeration system in your rink. Ice arenas serve many different purposes, from weekend hockey tournaments to open skating to community events that don’t require ice at all. Having an updated control system that is designed to fit your unique building is key to maintaining control and keeping everything running as it should. No matter how many rinks your arena has, or if the uses of the building change throughout the year, your custom refrigeration system should integrate seamlessly with your operations. Integrating fire alarm & life safety systems with the design can further improve the safety, comfort, and management of the building overall.

Egan Company’s Industrial Refrigeration Controls team partners with facility managers to learn what a well-designed system means for each facility, and how new controls and integrated systems can improve the way your rink is run.

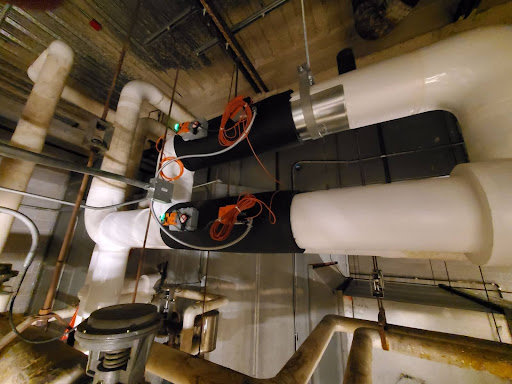

GLIDE EFFORTLESSLY WITH MODERN EQUIPMENT

Outdated or obsolete equipment can quickly become a pesky opponent blocking every attempt at reducing costs and stress when it comes to ice arena management. Modern advanced systems are designed to optimize energy and water consumption, leading to cost savings and ease of use. Built-in alarm systems offer instant notifications of malfunctions, expediting responses to emergency situations and keeping temperatures in check. Modern controls, including Egan’s Refrigeration-IQ™ Controls, can also improve equipment operation with a user-friendly interface, automation features, customizable adjustments, and load sharing configurations. If unexpected downtime does occur, Egan’s 24/7/365 Service team is available to help get you back online and back on the ice quickly.

A ZAMBONI FOR YOUR CONTROLS SYSTEMS

Bringing in specialized experts for updated refrigeration system design, fire alarm, and building control integration is crucial for smooth ice and easier operations. Egan’s dedicated control team can provide in-house expertise and support needed to customize systems to your specific ice arena’s requirements and bring it all to life. With non-proprietary equipment and 24/7/365 service support, Egan’s Refrigeration-IQ™ Controls can help make managing your facility smoother, giving you greater control of your temperatures and a higher quality of ice. Get in touch to upgrade your arena.