From custom piping to complex sheet metal and plumbing systems, Egan Company’s Mechanical division is redefining what it means to deliver full-service solutions. Under the leadership of Ross Noak, Senior Vice President of Mechanical, the team brings deep technical knowledge, design flexibility, and a customer-first mindset to every project—from emergency repairs to multimillion-dollar builds.

Built for Any Job—Anytime, Anywhere

Egan’s mechanical capabilities span the full spectrum—from plan-and-spec construction to highly tailored Design/Build projects. Whether it’s a new facility, a remodel, or an urgent replacement, Egan’s team is equipped to handle it.

“Our project managers are well-versed in all four mechanical trades: pipefitting, plumbing, sheet metal, and millwrights,” said Noak. “That versatility means we can support just about any need, from a fast-track emergency repair to a long-term industrial upgrade.” Emergency projects are supported by Egan’s 24/7 service hotline, with responsive follow-up to assess, quote, and resolve larger repairs or system replacements as needed.

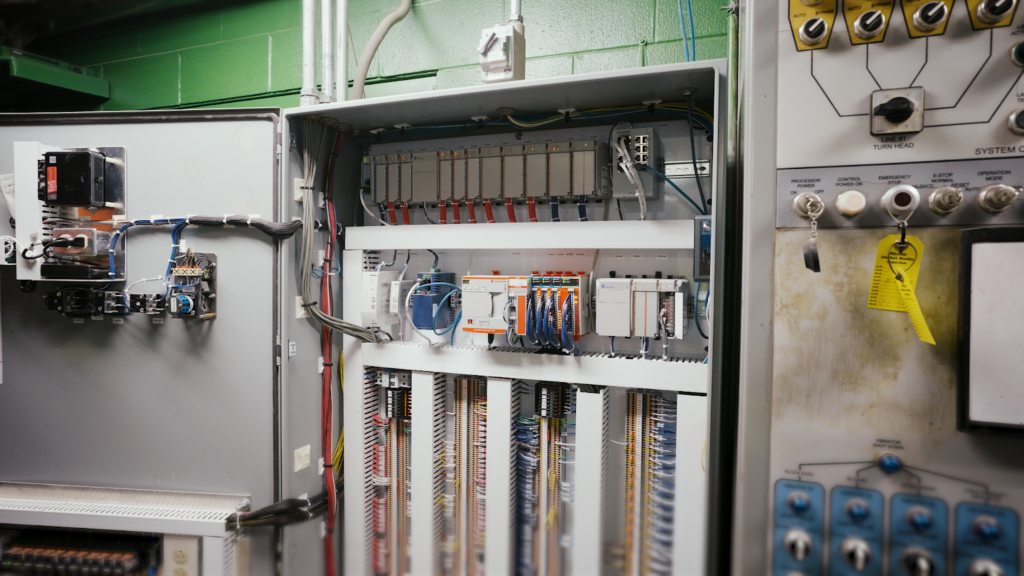

Mechanical systems installed by Egan’s team are as varied as the industries they serve. From commercial kitchens and bathrooms to medical gas systems, chilled water loops, and air handlers with electric reheat for green energy goals, the team adapts every solution to the customer’s specific needs. “Whether it’s boilers, chillers, or geo systems—we’re helping our customers reach their economic and environmental targets,” Noak explained. “We even do custom ductwork with logos or color schemes to match a company’s branding.”

Safety, Quality, and Consistency—By Design

All mechanical tradespeople at Egan are licensed and union-trained, and every project includes a dedicated core team to ensure quality and consistency. The trades teams conduct daily field reports, and QA/QC processes, customer site walks, and coordinated check-ins help keep each project on track. “It’s not just about code compliance,” said Noak. “It’s about building it right the first time and delivering an experience the customer can trust.”

From laser scanning to 3D modeling, Egan uses preconstruction tools to visualize complex installs and reduce risks before boots hit the ground. “Prefabrication saves time, reduces jobsite congestion, and improves safety,” said Noak. “We fabricate everything from piping systems to duct sections off-site and bring them in ready to install.”

One recent example is a data center project at the University of Minnesota, where prefabricated welds and offsets allowed the team to minimize disruption and improve project flow. “It’s probably in our shop right now,” he said. “Prefab always makes a difference.”

Serving More Than a Single Project

Half of Egan Mechanical’s work is owner-direct—and most of those customers are repeat. Every customer is paired with a dedicated project manager who provides ongoing support, from multi-year budgeting to quick-turn facility upgrades. “Our repeat rate is high because customers know we’re reliable,” Noak said. “We don’t just do one part—we offer all four mechanical services. Most competitors can’t say that.”

Egan’s ability to deliver across pipefitting, plumbing, sheet metal, and millwrights is a clear advantage. “Customers love that they can work with a single PM for everything. It simplifies their process and strengthens the outcome,” said Noak.

What Customers Often Miss? The Power of Planning

While prefabrication requires more upfront coordination, the payoff is substantial. “Customers often underestimate the time we save on-site when systems are pre-planned and built off-site,” Noak said. “There might be less visible activity at the beginning, but the work is happening—it’s just happening behind the scenes in our shop.”

Whether supporting a local business or powering a first-of-its-kind hydrogen generator, Egan’s Mechanical team brings more to leverage every step of the way. “We’re not just tradespeople—we’re problem solvers,” said Noak. “With all four mechanical services under one roof, we offer more value, more coordination, and more certainty from start to finish.”