News

Compressed Schedule Calls for Cross-Trade Coordination

September 20, 2014

The side-effects of the deluge of rain we received this last spring are still being felt today. On top of flooding and lake closures, there was a direct impact on construction projects that had to push back start dates because of wet soil.

The side-effects of the deluge of rain we received this last spring are still being felt today. On top of flooding and lake closures, there was a direct impact on construction projects that had to push back start dates because of wet soil.

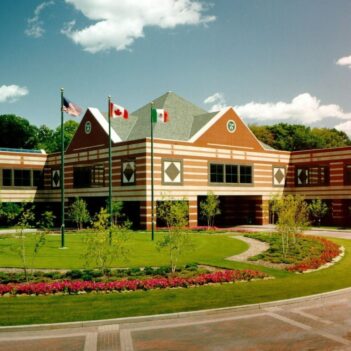

New building construction for the Lakes International Language Academy (LILA) adopted an aggressive new timeline to combat this obstacle. The K-6 charter school looked to build upon the success of its tuition-free immersion program (Spanish or Chinese) that follows an accredited International Baccalaureate Primary Years curriculum in the form of a new facility.

The rain, while good for flowers, turned the work site into a challenge. The foundation’s soil turned to soft clay, making for a less-than-ideal work environment. In fact, a concrete composite had to be mixed into areas where soil integrity was most vulnerable, effectively turning the school’s new parking lot into a great big cinder block.

Egan’s Electrical, Mechanical, and Building Systems & Services groups partnered with general contractor Kraus-Anderson to find a way to get the job done on time.

Egan’s Electrical, Mechanical, and Building Systems & Services groups partnered with general contractor Kraus-Anderson to find a way to get the job done on time.

Collaboration between Egan and Kraus-Anderson’s Project Manager Jake Boerboon and Superintendent Jesse Fiskewold were essential to project success. Even closer coordination was required than is customary for a project like this. Potentials for lost-time or further delays were addressed and resolved before the fact, creating an extremely well-organized work model.

Design/Build was also a huge factor in facilitating the accelerated timeline. Thanks to Egan doing the design and construction, many issues were resolved before they could reach the field. Without this, on-site problem solving would be a necessity and could have delayed the project further.

The construction team benefited greatly from prefabrication on this project. Circuits and feeders were crafted in-house and pre-assembly of the duct helped reduce installation time in the field. Close coordination between mechanical and electrical also minimized penetrations in the precast and allowed coordination of hanger systems, nearly cutting the initial estimate time in half.

Egan also supplied the academy’s building automation system. The weather delay shortened the installation timeframe significantly, requiring work to be completed in about a week.

The project finished on time, giving the school about two weeks to furnish and organize the building to be student-ready for the Fall.

The Lakes International Language Academy Project is a newly constructed, 43,000 square foot, two-story facility that included two parking lots and a gymnasium. The building’s automation system included integrating seven Lennox RTUs, installing controls on VAV boxes, and interlocking the kitchen make up unit with miscellaneous exhaust fans.

Core project team: LILA Building Co. and Kraus-Anderson Construction Company

Egan services performed: Design Build of Mechanical, Plumbing, Electrical Systems, and Building Automation Systems