News

Smarter Refrigeration Controls Start Here

May 12, 2025

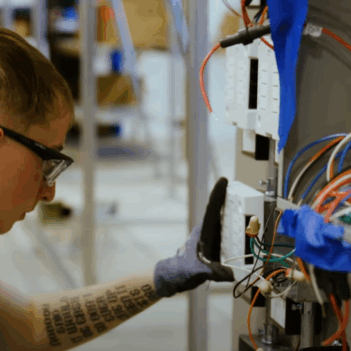

Intelligent. Efficient. Innovative. Refrigeration-IQ™ represents a new era of refrigeration control—where simplicity meets advanced performance. At Egan Company, it’s not about adding complexity, but about rethinking the standard to make systems smarter, more efficient, and more intuitive from the ground up. We had the chance to sit down with Dan Reintjes, Industrial Controls Project Manager and Tim Leahy, Industrial Controls Operations Supervisor for an inside look at everything you need to know about refrigeration controls.

What Are Refrigeration Controls and Why Do They Matter?

Refrigeration controls are the systems that manage and regulate how commercial and industrial refrigeration equipment operates. From keeping food safe in massive distribution centers to maintaining precise temperatures in pharmaceutical facilities, these controls ensure everything runs efficiently, reliably, and within strict temperature ranges. It can include sensors, control panels, programmable logic controllers (PLCs), remote monitoring, and energy management tools—all working together to help facilities reduce waste, avoid costly breakdowns, and optimize performance.

At the center of this evolution is Egan Company’s Refrigeration Controls team, a group known for its deep expertise and hands-on approach. With decades of combined experience, Leahy and Reintjes have helped shape some of the most advanced refrigeration projects across the country.

“We don’t just install a system and move on,” said Reintjes. “We’re thinking about what makes sense for your operators, your equipment, and your long-term goals. We want to leave you with something you understand and can manage—something you own.”

Empowering Operators from Day One

That idea of ownership is central to how Egan designs its Refrigeration-IQ™ systems. Built on an open platform, customers are given full transparency and control—no proprietary lock-ins, no excessive service fees, and no need to go back to the manufacturer for changes. “We’re giving customers the keys,” Leahy said. “Other contractors don’t do that. We want them to have the power to make changes or fixes without going through hoops.”

Designed to Fit – Not Force

From brand-new installations to complex retrofits, every system is tailored to the site, operators, and existing infrastructure. Often built and tested in-house, Egan’s solutions are delivered with minimal disruption—even in fully operational facilities.

“In some installs, we didn’t need to shut anything down,” said Reintjes. “It’s about making upgrades seamless.” A standout example? A nationwide rollout of 23 modular refrigeration skids for a confidential distribution client. Every unit was pre-wired, pre-tested, and delivered ready to plug in and power up.

But the team’s real advantage came well before equipment hit the jobsite. “We start every project with boots on the ground,” said Leahy. “Not just quoting off drawings—but walking the space, asking the right questions, and designing for how the system will actually be used.”

Support That Stays

Even after systems go live, support doesn’t stop. Egan’s team provides 24/7 troubleshooting, remote diagnostics, and ongoing optimization. Whether dealing with legacy systems or facilities without documentation, they’re ready to dive in—rewiring, rebuilding, and restoring full functionality with limited downtime.

“We’ve worked in places where nothing was labeled, and nothing had been touched in 30 years,” said Reintjes. “Those jobs don’t intimidate us. That’s where experience really shows.”

Efficiency at the Core

Beyond functionality, Egan’s approach helps customers reduce energy use, prolong equipment life, and cut costs—often without major overhauls. “If a system is running more compressors than necessary, we’ll scale it back,” said Reintjes. “We’ve helped customers avoid energy peaks, lower their utility bills, and run leaner.” And everything—from panel design to programming to construction within Egan’s UL 508A Panel Shop—is fully documented and handed over to the client. It’s a level of transparency that makes long-term system management easier and more cost-effective. For customers looking to modernize, expand, or simply gain more control over their systems, Egan offers more than just installation—they offer partnership.

“We’re here from the first walkthrough to long after the system is up and running,” said Leahy. “Because smarter refrigeration isn’t just about hardware—it’s about the people who use it every day.”