News

How Robotics Is Reshaping Jobsites

May 14, 2025

What’s Trending? Robotics in Construction

As the construction industry continues to evolve, one trend gaining momentum is the use of robotic automation to drive smarter, safer, and more efficient jobsites. Egan Company is actively applying this innovation through its InterClad team, pushing the boundaries of what’s possible in curtainwall, glass, and glazing layout and installation.

Through a hands-on partnership with Raise Robotics, Egan has introduced robotic scanning and layout solutions directly to the field. These tools are helping crews reduce risk, improve accuracy, and boost productivity on a wide variety of façade-focused projects—from high-rise curtainwall systems to intricate glass panel installations.

Smarter Layout, Reduced Risk

Layout is a foundational step in curtainwall and glazing work. Every detail—from anchor points to alignment—must be precisely marked before panels are set. Robotic layout systems, such as The Wright robot, enable the InterClad team to perform this task faster and with greater accuracy than traditional methods.

By automating layout on complex elevations and irregular slab edges, these systems minimize the potential for error and rework—saving both time and materials. The result: tighter schedules, more reliable installations, and a more consistent finished product.

Equally important, the technology enhances safety. With an extended reach beyond slab edges and into hard-to-access zones, the robot performs tasks that would otherwise expose workers to fall risks or unsafe conditions. Crews can stay out of harm’s way without slowing progress on site.

Flexibility on the Jobsite

The strength of mobile robotic platforms lies in their flexibility. These machines can now switch between multiple tools and functions, taking on a range of critical applications—from layout and inspections to drilling and fastener installation.

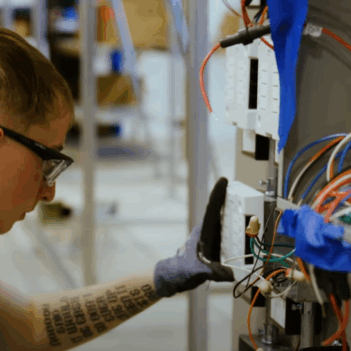

By integrating into existing workflows, these robotic tools are designed to complement skilled tradespeople rather than replace them. They take on repetitive or high-risk tasks, allowing teams to focus on work that requires craftsmanship and expertise.

Leading with Technology and Expertise

Egan remains committed to advancing the way construction is done. “The Raise Robotics team is on the forefront of innovation in our industry, and InterClad is excited to partner with them to advance our commitment to safety, quality, and continuous improvement,” said Ryan Woodruff, Egan Company Vice President of InterClad. For the InterClad team, the integration of robotic technology is not just a leap in capability—it reflects a continued dedication to precision, quality, and safety on every curtainwall and glazing project.

From skyscrapers to statement facades, Egan’s customers benefit from robotics-driven precision, efficiency, and quality, earning their confidence and exceeding expectations.