News

Building Smarter, Faster, and Safer with Electrical Prefabrication

December 12, 2025

Powering Precision: Inside Egan’s Electrical Prefabrication Process

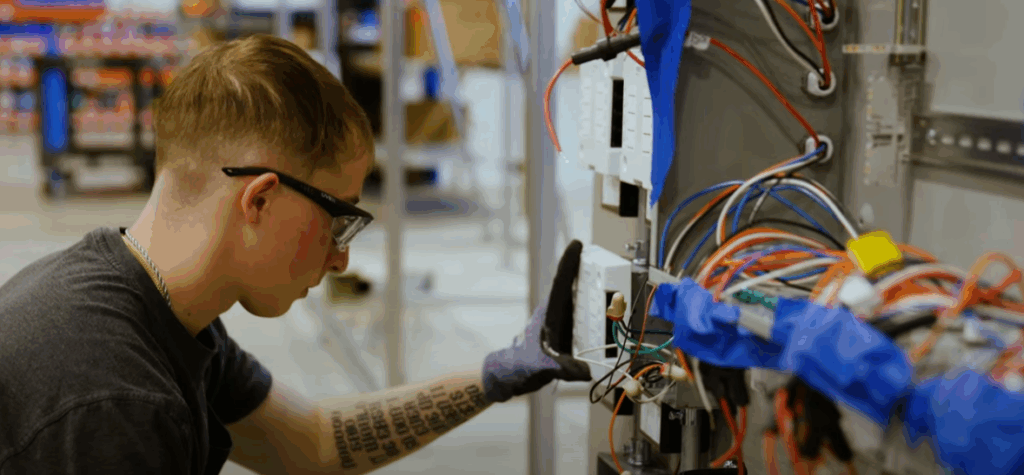

When it comes to electrical systems, precision and timing are everything. At Egan Company, our Electrical Prefabrication team takes both to the next level, combining innovation, collaboration, and control to deliver smarter, faster, and safer solutions to every project.

We sat down with Eric Lauwagie, Electrical Solutions & Prefabrication Manager, and Greg Hansen, Electrical Prefabrication Supervisor, to discuss what sets Egan’s electrical prefabrication operations apart and how this approach continues to drive value across industries.

Building in a Controlled Environment

Prefabrication brings electrical work off the jobsite and into a controlled, weather-independent facility. “Working in a controlled environment eliminates weather delays, access limitations, and a lot of the variables you deal with on a jobsite,” said Hansen. “It creates predictability and lets us maintain a steady workflow year-round.”

Hansen added that Egan’s prefabrication environment is designed for consistency: “we have optimal lighting, climate control, and organized work areas, which all improve safety, quality, and efficiency. Materials and tools are readily available, so union electricians can focus on precise, repetitive builds without interruptions.” The result? A seamless flow of assemblies that are ready to install the moment they reach the field.

Maximizing Speed, Efficiency, and Cost Savings

Prefabrication doesn’t just mean earlier starts, it means faster finishes and reduced overall project costs. “We can build assemblies for the next phase of the project while the field team installs what was built the week before,” Lauwagie explained. “That parallel workflow is huge for staying on schedule.” By moving much of the labor from the field to a streamlined environment, Egan reduces overall project hours, waste, and rework. Hansen noted, “Assemblies are built in parallel with other site work, compressing the schedule. Customers benefit from fewer disruptions, optimized manpower, and greater project predictability.”

Prefabrication Capabilities That Power Every Project

Egan’s Electrical Prefabrication Shop supports a wide range of assemblies and systems that are designed to simplify installation, improve quality, and enhance safety in the field. From temporary power and underground duct banks to lighting, room kitting, and complex distribution systems, each assembly is custom-built to the project’s needs.

Common builds include components like cable tray, conduit racks, rebar cages, switch and receptacle assemblies, transformer whips, fixture whips, and prewired light poles, just to name a few. “Prefabrication is a driving force that influences project planning, design coordination, and field execution,” Hansen explained. “For every phase–from underground work to final trim, our goal is always the same—deliver assemblies that arrive fully prepped, consistent, and ready to install.”

Collaboration That Keeps Projects Moving

Success in prefabrication starts with communication. “We work hand-in-hand with field leaders, superintendents, and project managers throughout the project,” Lauwagie said. “Regular meetings, shared visibility, and approval checkpoints make sure everyone’s aligned from start to finish.” This collaborative process ensures that assemblies are built to exact specifications and delivered when—and how—the field needs them.

Bringing Value Across Industries

From new construction and manufacturing facilities to mission-critical environments like data centers or healthcare, Egan’s electrical prefabrication approach delivers consistency where it matters most. “Highly complex projects with multiple trades or tight timelines benefit the most,” said Lauwagie. “When space is limited or conditions are harsh, prefabrication allows us to build safely and efficiently offsite.” And because Egan’s teams handle electrical, mechanical, and technology systems under one roof, customers gain the advantage of true multi-trade coordination. “Our VDC teams work side by side across trades to eliminate clashes and streamline planning,” said Hansen. “It’s all about delivering integrated, installation-ready solutions.”

Building Smarter, Together

For Egan, electrical prefabrication isn’t just about saving time—it’s about raising the standard of what’s possible in the field. With every project, the team continues to refine processes, improve quality, and deliver value-driven results to customers across every industry. “Prefabrication is about thinking ahead,” Lauwagie said. “It’s planning, coordination, and execution—done right the first time.”