News

Mechanical Prefabrication that Builds Certainty

February 20, 2026

What if critical mechanical work could begin before crews ever arrive on site? Oh wait, it can. For Egan Company, prefabrication is a key solution to bring those elements together earlier in the process, reducing risk and creating more predictable outcomes on the job.

We recently sat down with Grant Heikes, Service Mechanical Operations Manager and Mike Finnegan, Mechanical Shops Foreman, to talk about how the company approaches piping and plumbing prefabrication, what happens long before crews arrive on site, and why a controlled shop environment can make a meaningful difference on complex projects.

Starting the Work Before the Work Begins

Mechanical prefabrication is not a single step. It is the result of conversations that begin well before fabrication or installation starts.

“Conversations happen early,” Heikes said. “Someone might come to us and say, ‘We’re looking at this job, and if we get it, it’s starting in February.’ From there, we’re already talking about materials, scope, and what this job might require.”

Those early discussions often take place during estimating or preconstruction and continue once a project is awarded. At that point, engineering, virtual construction, and operations teams begin working together to determine what portions of the piping system should be fabricated in the shop versus installed on the jobsite. From the shop side, that early planning directly impacts efficiency once fabrication begins. “When we know what’s coming and what materials are involved, we can plan the work properly instead of reacting later,” Finnegan said. “That preparation makes a big difference in how smoothly things run.”

Engineering With Fabrication in Mind

Once drawings are received, whether through a Design/Build or plan-and-spec approach, the project moves into a coordinated planning phase. Virtual construction teams model the system and develop spools for fabrication, while project and field leaders weigh in on sequencing and installation strategy. “At the kickoff meeting, there are real conversations about how much of the job will be fabricated in our shops and how much will be fabricated in the field,” Heikes said. “That’s where alignment starts.”

This coordination helps ensure fabricated components arrive on site in the right order and at the right time. Heikes compared it to assembling a kit that is designed to be installed efficiently, rather than sorting through parts after delivery. “You want things fabricated and loaded in a way that supports how the field is going to install it,” he said. “That takes communication between the shop and the field.”

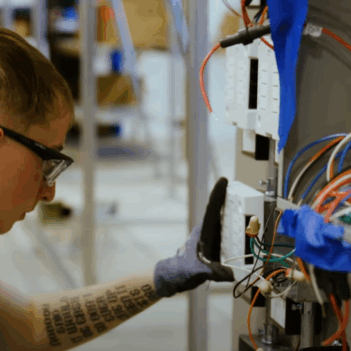

Safety and Consistency in a Controlled Environment

One of the biggest advantages of Egan’s piping and plumbing prefabrication process is the ability to perform work in a controlled shop setting. From a production standpoint, the shop environment also creates measurable efficiency gains. “The shop is indoors and climate controlled, which is an immediate advantage,” Finnegan said. “It allows one person to perform tasks that usually require two people in the field.”

Specialized equipment further supports productivity. “We have equipment that turns the pipe for us while we weld,” Finnegan explained. “That means we can complete a weld without manually stopping to reposition it. It reduces physical fatigue and allows for more consistent, daily production.” By contrast, field conditions can introduce challenges ranging from limited space to coordination with other trades. Prefab helps reduce congestion on site and allows field crews to focus on safe installation rather than assembly.

Advanced Materials and Skilled Fabrication

The mechanical shop supports a wide range of materials, including carbon steel, stainless steel, and specialty alloys that require experienced welders and precise processes. “We have the capabilities to weld just about any kind of material,” Finnegan said. “We frequently weld stainless steel, but we’ve also worked with chrome alloys and other high-nickel alloys. We have the equipment and experience to provide that for our customers.”

Heikes emphasized that this capability is not universal. “We have highly skilled people in the shop who can fabricate different types of metals,” he said. “Not every shop can do that or consistently meet the requirements.” Certain projects require welds that must pass X-ray inspection, adding another layer of quality control. According to Heikes, that capability is the result of both experienced tradespeople and established processes.

More to Leverage in Mechanical Work

For Egan, prefabrication is not just about efficiency. It’s about foresight, coordination, and creating better conditions for both shop and field crews. “Mechanical prefabrication is really about planning,” Heikes said. “It’s about asking early on, ‘What makes the most sense to build ahead of time, and how do we support the people installing it?’” By starting work earlier, controlling variables and aligning teams from the beginning, mechanical prefabrication becomes a strategic advantage, one that often goes unnoticed, but makes all the difference.