News

Inside the World of Millwrights

October 22, 2025

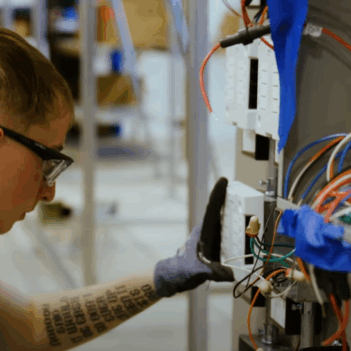

Behind every efficient production line or manufacturing facility is a team ensuring the equipment is installed and maintained correctly. That’s where Egan Company’s millwright team brings the expertise, precision, and attention to detail needed to install, repair, and maintain the machines that power industries across the region. Recently, we sat down with Project Managers Taylor Sebesta and Dominic Digatono to share how Egan’s millwrights approach complex mechanical work and what sets the Egan team apart.

Exploring the Craft of Millwrights

Simply put, millwrights are responsible for installing, maintaining, and repairing the machinery that keeps industrial and manufacturing operations moving. “It’s a wide range of work,” said Sebesta. “We build and install everything from conveyor systems and motors to gearboxes and shafts in plants across Minnesota and beyond.”

While some projects involve assembling new equipment, others focus on maintenance—such as bearing replacement, conveyor upkeep, or gearbox repair. “Anything that moves in a manufacturing facility often involves millwrights to keep it going or to fix it,” added Digatono.

From Planning to Precision

Every project looks different, but the end goal is always the same: ensure safe, reliable equipment performance. “Most of the time, we’re brought in to assemble and install the machinery that customers purchase,” explained Sebesta. “We’ll coordinate from the moment it lands at the facility’s loading dock to when it’s in place and operational.”

Millwrights handle precision alignment and leveling to ensure machinery functions properly and lasts longer. “If it’s not aligned, the machinery shakes itself apart faster,” said Digatono. “Proper alignment minimizes wear and tear and keeps systems running smoothly.”

Problem-Solving in Action

Installing or moving large industrial equipment is rarely straightforward, and that’s where the years of experience and the team’s problem-solving skills come in.

“Many facilities were built around the equipment,” said Digatono. “So getting an old piece out and a new piece in can be a huge challenge. Sometimes we have to develop creative rigging solutions or move pieces in sections to make it work.” Sebesta agreed. “Every project is unique. It’s very situational and depends on the space, the machinery, and the customer’s operations.”

Working with heavy, complex machinery presents risks and Egan’s millwrights approach every task with safety as their top priority. “If we can’t do a job safely, we either tell the customer how we can do it safely or we’re not doing it,” said Sebesta.

Collaboration Across Trades

While Egan’s millwrights primarily support manufacturing and distribution facilities, their projects often involve coordination with other trades—particularly mechanical and electrical teams. “Being part of a larger company gives customers an advantage,” said Digatono. “Even when multiple project managers are involved, coordination between Egan teams is seamless compared to working with several outside contractors.”

Collaboration ensures efficiency and reduces downtime. “From start to finish, we work to minimize disruption to customer operations and communicate early if challenges arise,” Sebesta said.

Millwrights bring extensive experience across industries, from food and beverage to power and district energy. That range makes the team well-equipped to tackle unique and demanding projects. “We’re pretty adaptable,” said Sebesta. “Most of the time, it’s not the first instance our team has seen a specific challenge—and that makes a big difference.” For companies looking to keep operations running smoothly or tackle a complex equipment installation, Egan’s millwrights provide the expertise, precision, and safety-focused approach needed to get the job done. Contact us today to see how our team can support your millwright needs.