High-rise buildings are the distinguishing trademark of cities around the world. And, being the 16th largest metropolitan area in the country, Minneapolis and St. Paul are no different.

High-rise buildings are the distinguishing trademark of cities around the world. And, being the 16th largest metropolitan area in the country, Minneapolis and St. Paul are no different.

As a specialty contractor, Egan has played a role in helping to build, remodel, and maintain many of these high-rise buildings that help shape the Twin Cities’ skyline. While these projects have included scopes of all sizes, this past spring brought forth a very unique high-rise venture.

Egan’s team was utilized for a highly-specialized project in downtown St. Paul, Minn. The scope included the replacement of four massive cooling towers located on the rooftop of Galtier Tower – a staggering 31 stories from the ground.

Galtier Tower is one of two high-rise towers that make up the city block called Cray Plaza. The plaza also includes two other commercial buildings. Together, the block boasts hundreds of apartments and luxury condominiums, a small preparatory school, YMCA facility, and an assortment of other retail space – all of which fully rely on these cooling towers to air condition their buildings.

Overall, the project would require the tallest crane in Minnesota, in-house design and prefabrication, and even more pre-planning and coordination to complete the job within the compressed schedule.

Navigating a Tight Schedule

The project was officially awarded to Egan by Bigos Management in late March. From the start, Egan’s team knew the new cooling towers would need to be “flown” up to the top of the building. To do the “flying”, Egan began coordinating and pre-planning with a local crane company, Vic’s Crane and Heavy Haul.

The project was officially awarded to Egan by Bigos Management in late March. From the start, Egan’s team knew the new cooling towers would need to be “flown” up to the top of the building. To do the “flying”, Egan began coordinating and pre-planning with a local crane company, Vic’s Crane and Heavy Haul.

An in-depth, engineered lift (or often called “pick”) plan was created while Egan’s team began designing the piping and support systems for the towers. A structural engineer was also hired to design the steel platforms for beneath each cooling tower based on the drawings provided by Egan.

Vic’s crane, standing at 410 feet tall, was tasked to hoist these four new cooling towers onto Galtier. However, driving a monster crane into a heavily populated urban city isn’t the most practical of tasks.

In the weeks prior to setting up the crane downtown, the city of St. Paul removed a light pole, cut down a tree, and approved and coordinated road closures. Vic’s also obtained multiple permits, clearances, and police support. Once complete, the crane took 12 hours to set-up on the street.

Another unique aspect of this project was that the new piping system for the cooling towers utilized Aquatherm – a fairly new type of system that is an environmentally friendly alternative to metal. Though extremely lightweight (and vibrantly colored!), Aquatherm pipe is one of the longest-lasting and most chemically inert piping material available.

Egan’s fabrication shop prefabricated all of the Aquatherm piping system for this job. It was also specifically designed so it could fit into the 7’7” elevator and transported to the rooftop of Galtier.

The Race to the Top

Although there was two feet of snow on the ground when the project started, Minnesota’s infamously, unpredictable spring weather found itself over 85 degrees just a few weeks later. With the previous cooling towers entirely off the building, the countdown was on to get the first new cooling tower operational in order to start cooling all of the buildings within the city block.

Although there was two feet of snow on the ground when the project started, Minnesota’s infamously, unpredictable spring weather found itself over 85 degrees just a few weeks later. With the previous cooling towers entirely off the building, the countdown was on to get the first new cooling tower operational in order to start cooling all of the buildings within the city block.

At the top of Galtier, Egan’s team worked with a subcontractor to set up an extensive amount of scaffolding so the team of pipefitters, electricians, and controls electricians could safely access the work. All of the prefabricated Aquatherm and structural steel platforms were also set before the crane could “fly” the cooling towers to the roof.

The first weekend of May, less than six weeks after being awarded the project, Egan’s team, alongside Vic’s, successfully lifted and installed all four cooling towers onto Galtier. The compressed schedule… accomplished.

Egan installed a majority of the piping after the cooling towers were set and officially completed the project in July.

Core Project Team: Bigos Management, Vic’s Crane and Heavy Haul

Services Provided: Cooling towers replacement, pipe fabrication, pipefitting, electrical controls, electrical installation

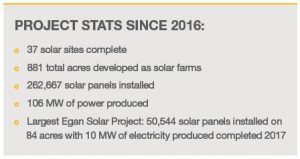

Egan’s solar site projects vary in size, location, time of year, and type of solar panels – fixed-tilt or tracking. “Tracking” solar panels track the sun’s progress across the sky throughout the day, whereas the fixed-tilt solar panels stay in place. Last summer, 150 Egan electricians were on the 65-acre St. Joseph Solar Farm project to install 28,188 fixed-tilt solar panels.

Egan’s solar site projects vary in size, location, time of year, and type of solar panels – fixed-tilt or tracking. “Tracking” solar panels track the sun’s progress across the sky throughout the day, whereas the fixed-tilt solar panels stay in place. Last summer, 150 Egan electricians were on the 65-acre St. Joseph Solar Farm project to install 28,188 fixed-tilt solar panels.

T3

T3 versity of Minnesota Bee and Pollinator Lab

versity of Minnesota Bee and Pollinator Lab U.S. Bank Stadium

U.S. Bank Stadium Wells Fargo Downtown East Corporate Campus

Wells Fargo Downtown East Corporate Campus  energy absorbed through the solar panels passes through Photovoltaic cables in the racks and inverters, converting the power to transmission voltage.

energy absorbed through the solar panels passes through Photovoltaic cables in the racks and inverters, converting the power to transmission voltage. With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated.

With these new innovations, farmers were able to produce and distribute crops at a more rapid pace, creating a need for more automated processes. To fill this need, many of Minnesota’s largest companies began to revolutionize the food industry even further by making production simpler and more automated. production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called.

production on a farm/ranch, processing in a manufacturing facility, distribution to stores/restaurants, and consumption at a home/restaurant. But there’s a lot that goes into the processing step that many people don’t realize. Equipment needs to frequently be moved or upgraded, production lines require routine maintenance, facilities are expanded – and that’s when Egan Company is called. Ohio-based UltraFlo. Given its design – clean, simple, and free of cluttered pipes or wires – it was perfect for the highly trafficked, rarely closed bathrooms of the casinos.

Ohio-based UltraFlo. Given its design – clean, simple, and free of cluttered pipes or wires – it was perfect for the highly trafficked, rarely closed bathrooms of the casinos. Another major cost saving perk is its one mixing valve system, which allows maintenance personnel to adjust the faucet temperature for the entire bathroom through a single valve. This differs from battery-operated systems, which each have their own controls, resulting in a very costly and time-consuming process when maintenance is needed.

Another major cost saving perk is its one mixing valve system, which allows maintenance personnel to adjust the faucet temperature for the entire bathroom through a single valve. This differs from battery-operated systems, which each have their own controls, resulting in a very costly and time-consuming process when maintenance is needed. At a local warehouse for an international food distribution company, forklifts had triggered traditional sprinklers in the freezer section by accidentally hitting them when moving products. The cost

At a local warehouse for an international food distribution company, forklifts had triggered traditional sprinklers in the freezer section by accidentally hitting them when moving products. The cost A challenge with the new system was that a traditional heat detector could not be installed due to it being part of the sprinkler head – which a forklift could (once again) hit. To overcome this challenge, Egan installed a specially-engineered cable connected directly to the sprinkler pipe. If that cable reaches a specific temperature, the alarm will set off the sprinklers.

A challenge with the new system was that a traditional heat detector could not be installed due to it being part of the sprinkler head – which a forklift could (once again) hit. To overcome this challenge, Egan installed a specially-engineered cable connected directly to the sprinkler pipe. If that cable reaches a specific temperature, the alarm will set off the sprinklers.